1. What is the projected Compound Annual Growth Rate (CAGR) of the Injection Grade Polyolefin Plastomer?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Injection Grade Polyolefin Plastomer

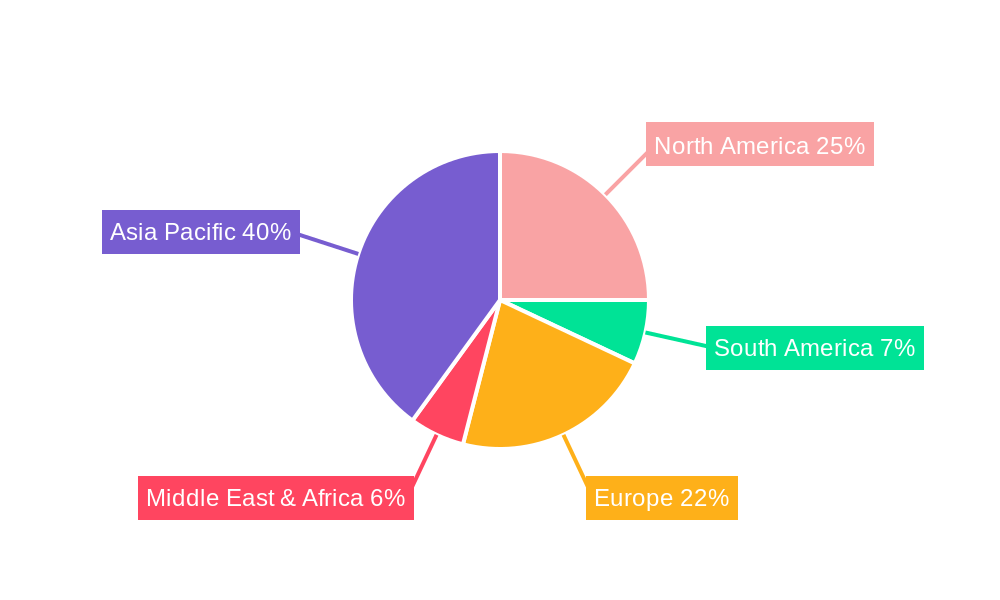

Injection Grade Polyolefin PlastomerInjection Grade Polyolefin Plastomer by Type (Low Linear Type, High Linear Type, World Injection Grade Polyolefin Plastomer Production ), by Application (Automotive, Consumer Product, Wire & Cable, Packaging Products, Others, World Injection Grade Polyolefin Plastomer Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

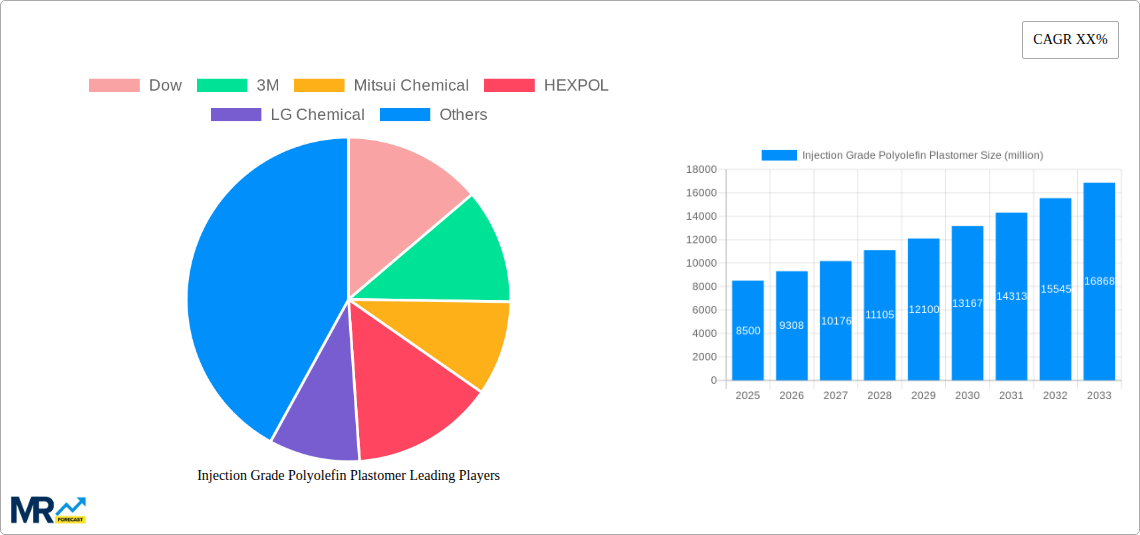

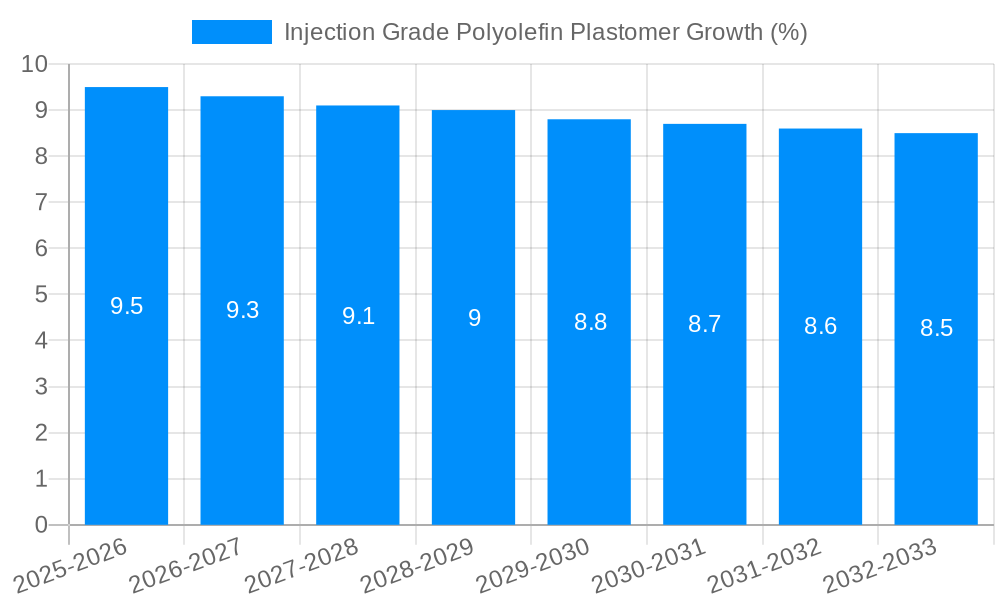

The global Injection Grade Polyolefin Plastomer market is poised for significant expansion, projected to reach an estimated USD 8,500 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of 9.5% extending through 2033. This growth is primarily fueled by the escalating demand for lightweight and versatile materials across key end-use industries, notably automotive and packaging. The automotive sector is increasingly adopting polyolefin plastomers for interior components, exterior trim, and under-the-hood applications due to their excellent impact resistance, flexibility, and recyclability, directly contributing to vehicle weight reduction and fuel efficiency. Similarly, the packaging industry is leveraging these materials for their superior sealing properties, clarity, and durability, particularly in flexible packaging and rigid containers. Advancements in polymer technology, leading to enhanced performance characteristics and cost-effectiveness, further propel market adoption.

The market dynamics are further shaped by a confluence of trends and strategic initiatives by leading players. Innovations in low and high linear type plastomers are expanding their application spectrum, catering to more specialized requirements. Key market players such as Dow, ExxonMobil Chemical, SABIC SK Nexlene, and Borealis are actively investing in research and development to introduce novel formulations and sustainable solutions, addressing growing environmental concerns and regulatory pressures. While the market exhibits strong growth potential, certain restraints such as fluctuating raw material prices, particularly for polyolefins derived from crude oil, and the emergence of alternative high-performance polymers could pose challenges. However, the overarching demand for performance-driven, adaptable, and increasingly sustainable plastic solutions is expected to outweigh these limitations, ensuring sustained growth and innovation within the Injection Grade Polyolefin Plastomer landscape.

Here is a unique report description on Injection Grade Polyolefin Plastomer, incorporating your specified headings, values, and companies:

The global injection grade polyolefin plastomer market is poised for significant expansion, driven by an increasing demand for high-performance, lightweight, and versatile materials across a multitude of industries. Our comprehensive analysis, covering the Study Period: 2019-2033 and focusing on the Base Year: 2025 with a Forecast Period: 2025-2033, reveals a compelling growth trajectory. The Historical Period: 2019-2024 laid the groundwork for this burgeoning market, characterized by steady adoption and technological advancements. XXX key market insights indicate a strong preference for materials offering superior flexibility, impact resistance, and processing ease, all hallmarks of injection grade polyolefin plastomers. These elastomers are replacing traditional materials like PVC, rubber, and EVA in applications demanding enhanced durability and aesthetic appeal. The intricate balance between performance and cost-effectiveness is a critical factor influencing market dynamics. As manufacturers strive for greater efficiency and reduced environmental impact, the inherent recyclability and energy-efficient processing of polyolefin plastomers make them an increasingly attractive choice. Our report delves into the nuanced interplay of material science and market demand, highlighting how innovations in polymerization techniques are enabling the creation of specialized grades tailored for niche applications. The estimated production of World Injection Grade Polyolefin Plastomer Production is projected to reach hundreds of million units within the forecast period, underscoring the scale of this market. We will meticulously dissect the market segmentation, exploring the dominance of specific types and applications, and providing granular insights into regional consumption patterns. The ongoing evolution of manufacturing technologies, coupled with a growing awareness of sustainable material solutions, will continue to shape the trends within this dynamic sector. The transition towards lighter vehicles in the automotive industry, the demand for safer and more engaging consumer products, and the need for robust yet flexible materials in wire & cable and packaging are all contributing to this upward trend.

The burgeoning demand for injection grade polyolefin plastomers is propelled by a confluence of powerful market forces, primarily centered around material innovation and evolving industrial needs. The inherent properties of these plastomers – their exceptional flexibility, high impact strength, excellent abrasion resistance, and superior chemical inertness – make them ideal substitutes for traditional thermoset rubbers and commodity plastics. This performance advantage is particularly critical in sectors like automotive, where lightweighting initiatives are paramount for fuel efficiency and reduced emissions. The ability to achieve complex geometries with injection molding further enhances their appeal, allowing for integrated designs and reduced part counts. Moreover, the growing consumer preference for durable, aesthetically pleasing, and safe products across segments like consumer goods and packaging is directly fueling the adoption of these versatile materials. The increasing focus on sustainability and the circular economy also plays a crucial role; polyolefin plastomers are readily recyclable, aligning with global environmental regulations and corporate social responsibility goals. This makes them a sustainable alternative that doesn't compromise on performance. The continuous advancements in catalyst technology and polymerization processes are enabling producers to fine-tune the properties of these plastomers, creating specialized grades that cater to highly specific application requirements, thereby broadening their market penetration.

Despite the robust growth trajectory, the injection grade polyolefin plastomer market is not without its hurdles. One significant challenge is the price volatility of raw materials, primarily crude oil and natural gas, which are the foundational feedstocks for polyolefins. Fluctuations in these commodity prices can directly impact the manufacturing costs and, consequently, the pricing of the final plastomer products, affecting market affordability and demand. Another restraint stems from the strong competition posed by other established and emerging elastomeric materials. While polyolefin plastomers offer distinct advantages, traditional materials like silicone, thermoplastic elastomers (TPEs), and even certain specialty rubbers continue to hold significant market share in specific applications due to their well-understood properties and established supply chains. The technical expertise required for optimal processing of certain specialized grades of polyolefin plastomers can also be a barrier for some manufacturers, necessitating investment in new equipment or retraining of personnel. Furthermore, stringent regulatory requirements in some regions related to food contact, medical applications, or environmental impact can create compliance challenges and add to development costs. Finally, the inherent susceptibility of some polyolefin plastomers to UV degradation and high temperatures can limit their application in extremely harsh environments, necessitating the use of specialized additives or alternative materials.

The global injection grade polyolefin plastomer market is characterized by the dominant influence of specific regions and application segments, painting a clear picture of where the primary demand and innovation are centered.

Dominant Regions:

Dominant Segments:

The interplay between these dominant regions and segments creates a dynamic market landscape, with continuous innovation driven by the specific requirements and growth potentials within each area. The projected World Injection Grade Polyolefin Plastomer Production is heavily influenced by the consumption patterns in these key markets and segments.

Several key factors are acting as significant growth catalysts for the injection grade polyolefin plastomer industry. The ongoing advancements in polymerization technologies, particularly in metallocene catalysis, have enabled the production of plastomers with highly controlled molecular architectures. This allows for the fine-tuning of properties like density, melt flow, and elasticity, opening up new application possibilities. The increasing global emphasis on sustainability and the circular economy is another major catalyst, as polyolefin plastomers are inherently recyclable and offer a lower environmental footprint compared to some traditional materials. Furthermore, the expanding automotive sector's persistent need for lightweighting solutions to meet stricter fuel efficiency standards is a powerful driver. The growing demand for high-performance materials in consumer electronics, medical devices, and advanced packaging also contributes significantly to market expansion.

This report offers an exhaustive examination of the global injection grade polyolefin plastomer market, providing deep insights into its dynamics from 2019-2033. It meticulously analyzes the Base Year: 2025 and extends through the Forecast Period: 2025-2033, building upon the foundation laid during the Historical Period: 2019-2024. The report delves into the intricate trends, identifying key market drivers and the challenges that shape the industry landscape. It provides a granular breakdown of dominant regions and the most impactful application segments, including Automotive, Consumer Product, Wire & Cable, and Packaging Products, contributing to the projected World Injection Grade Polyolefin Plastomer Production figures in the hundreds of million units. Furthermore, it highlights the pivotal role of different plastomer types like Low Linear Type and High Linear Type. The report also profiles leading global manufacturers and details significant market developments, offering a comprehensive overview for stakeholders seeking to understand and capitalize on the opportunities within this dynamic sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Dow, 3M, Mitsui Chemical, HEXPOL, LG Chemical, Teknor Apex, ExxonMobil Chemical, Dynasol, SABIC SK Nexlene, RTP Company, Borealis, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Injection Grade Polyolefin Plastomer," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Injection Grade Polyolefin Plastomer, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.