1. What is the projected Compound Annual Growth Rate (CAGR) of the Honeycomb Sandwich for Automotive?

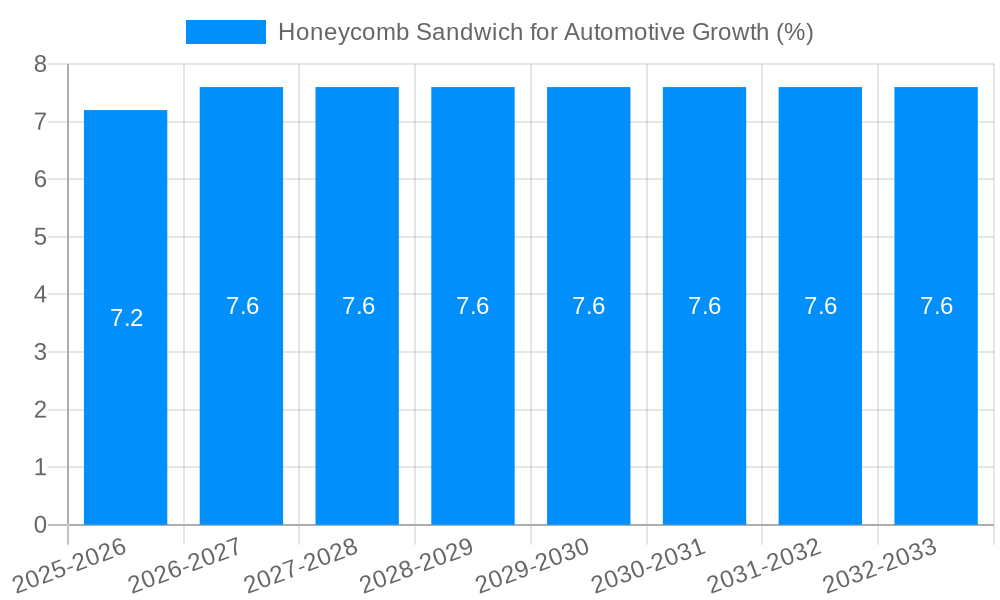

The projected CAGR is approximately 7.2%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Honeycomb Sandwich for Automotive

Honeycomb Sandwich for AutomotiveHoneycomb Sandwich for Automotive by Type (Aluminum, Steel, Composites, Others), by Application (Electric Vehicle, Fuel Vehicle), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

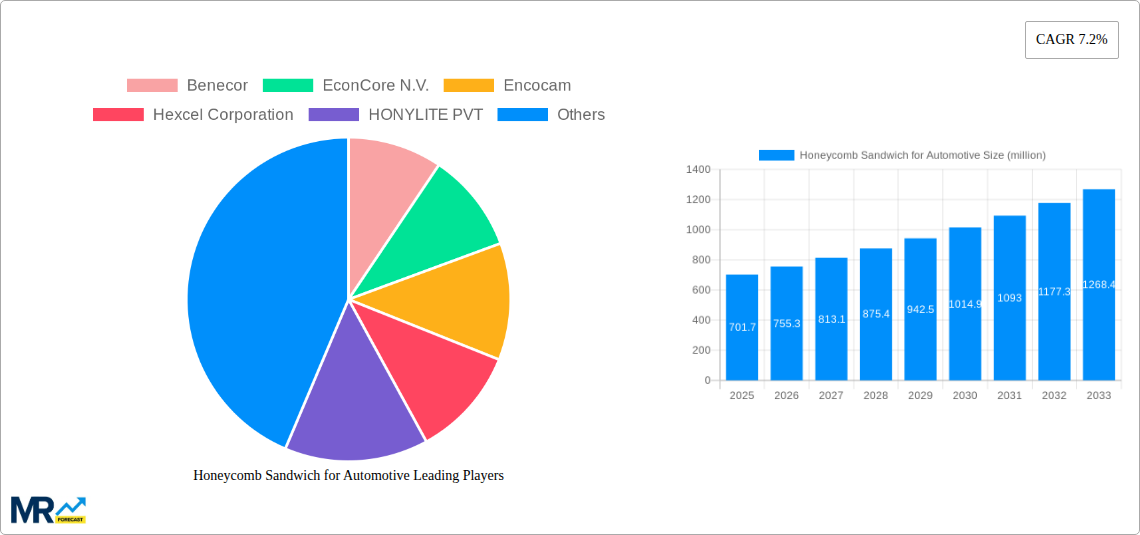

The global Honeycomb Sandwich for Automotive market is poised for significant expansion, projected to reach a substantial market size of $701.7 million by 2025. This growth trajectory is fueled by a robust Compound Annual Growth Rate (CAGR) of 7.2%, indicating a dynamic and evolving industry. A primary driver for this upward trend is the burgeoning demand for lightweight yet structurally sound materials in the automotive sector, particularly driven by the electric vehicle (EV) revolution. The inherent strength-to-weight ratio of honeycomb sandwich materials makes them ideal for improving vehicle efficiency, extending battery range in EVs, and enhancing overall performance in both electric and fuel-powered vehicles. Advancements in composite materials and manufacturing processes are further contributing to the market's expansion, offering tailored solutions for complex automotive designs. The increasing adoption of these advanced materials in structural components, interior panels, and battery enclosures underscores their growing importance in modern vehicle manufacturing.

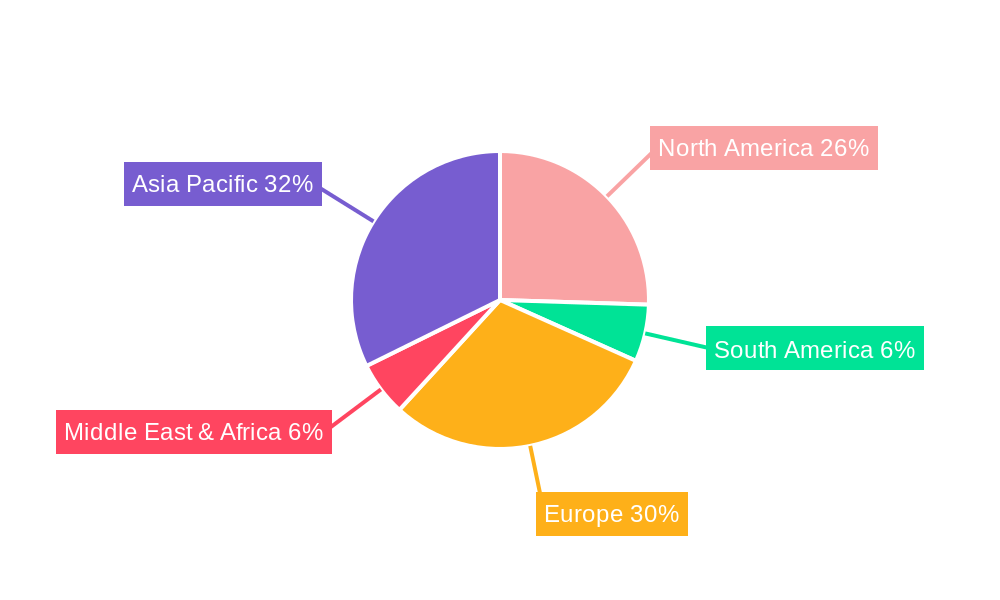

Emerging trends in the automotive industry, such as the focus on sustainability and stringent regulatory standards for fuel efficiency and emissions, are amplifying the need for innovative material solutions like honeycomb sandwiches. While the adoption of these advanced materials presents opportunities, certain restraints, such as the initial cost of manufacturing and integration complexities, may pose challenges. However, the continuous research and development in material science and production techniques are expected to mitigate these restraints over time. Key applications within the automotive industry include their use in electric vehicles, where weight reduction is paramount for performance and range, and in traditional fuel vehicles for enhanced structural integrity and weight savings. Geographically, the Asia Pacific region, led by China and India, is expected to witness substantial growth due to its dominant position in global automotive production and increasing adoption of EVs. North America and Europe, with their established automotive industries and strong focus on technological innovation, will also remain significant markets. The competitive landscape features key players like Hexcel Corporation, EconCore N.V., and Encocam, all actively contributing to market innovation and expansion.

This report delves into the dynamic and evolving Honeycomb Sandwich for Automotive market, providing an in-depth analysis of its current landscape and future trajectory. Spanning a comprehensive study period from 2019 to 2033, with a focus on the Base Year (2025) and a detailed Forecast Period (2025-2033), this research aims to equip stakeholders with critical market intelligence. The Historical Period (2019-2024) provides essential context for understanding past trends and their impact on the present market dynamics.

The report quantifies the market size in millions of units, offering a clear perspective on the scale and growth potential of this innovative material within the automotive industry. It examines various Segments including Type (Aluminum, Steel, Composites, Others) and Application (Electric Vehicle, Fuel Vehicle), as well as Industry Developments that are shaping the market.

The automotive industry is undergoing a transformative phase, driven by an insatiable demand for lightweight, high-strength, and sustainable materials. Honeycomb sandwich composites are emerging as a pivotal solution, poised to revolutionize vehicle design and manufacturing. XXX, a key market insight, highlights the escalating adoption of honeycomb structures as a direct response to stringent fuel efficiency regulations and the growing imperative for carbon footprint reduction. This trend is particularly pronounced in the Electric Vehicle (EV) segment, where weight reduction is paramount for maximizing battery range and overall vehicle performance. The inherent structural integrity and energy absorption capabilities of honeycomb materials make them ideal for battery enclosures, structural components, and interior panels, contributing significantly to vehicle safety and passenger comfort. Furthermore, advancements in manufacturing techniques, such as automated fiber placement and resin infusion, are enabling the production of complex honeycomb structures at a more competitive cost, thereby accelerating their integration into mainstream automotive platforms. The "lightweighting" revolution is no longer a niche aspiration but a core strategic imperative for automakers worldwide, and honeycomb sandwich technology stands at the forefront of this paradigm shift. The versatility of honeycomb structures, allowing for tailored properties based on core material and facing sheet selection, further solidifies their position as a go-to material for addressing diverse automotive challenges. From enhancing crashworthiness to improving NVH (Noise, Vibration, and Harshness) characteristics, the multifaceted benefits of honeycomb composites are driving their widespread acceptance and promising sustained growth in the coming years. The increasing focus on circular economy principles also favors honeycomb materials due to their recyclability and potential for use in multi-material designs, aligning with the industry's sustainability goals. The evolving regulatory landscape, pushing for safer and more fuel-efficient vehicles, acts as a strong tailwind for the adoption of advanced materials like honeycomb sandwich structures.

The surge in the adoption of honeycomb sandwich materials in the automotive sector is propelled by a confluence of potent forces. Foremost among these is the relentless pursuit of lightweighting. Automakers are under immense pressure to reduce vehicle weight to meet increasingly stringent fuel efficiency standards and extend the driving range of electric vehicles. Honeycomb structures, with their exceptional strength-to-weight ratio, offer a compelling solution by replacing heavier traditional materials like steel and aluminum without compromising structural integrity. This weight reduction translates directly into improved fuel economy for internal combustion engine vehicles and enhanced battery performance for EVs. Secondly, the growing emphasis on sustainability and environmental responsibility is a significant driver. Honeycomb composites, particularly those utilizing advanced composites, contribute to a lower carbon footprint throughout the vehicle lifecycle, from manufacturing to end-of-life recycling. The ability to integrate advanced manufacturing processes that minimize waste further bolsters their eco-friendly credentials. Thirdly, enhanced safety performance is a critical factor. The inherent energy-absorbing properties of honeycomb structures make them ideal for critical safety applications, such as impact absorption in chassis components and battery protection systems, thereby improving overall vehicle safety and occupant protection. The intrinsic stiffness and rigidity of honeycomb panels also contribute to improved structural integrity and crashworthiness.

Despite its compelling advantages, the widespread adoption of honeycomb sandwich materials in the automotive industry faces several significant challenges and restraints. One of the primary hurdles is cost. While manufacturing processes are advancing, the initial investment in tooling and specialized equipment for producing complex honeycomb structures can be substantial, making them more expensive than conventional materials, especially for mass-market vehicles. This cost factor can limit their application to higher-end models or specific performance-critical components. Another challenge lies in manufacturing complexity and scalability. Producing large, intricate honeycomb parts consistently and at high volumes requires sophisticated manufacturing techniques and stringent quality control measures. Scaling up production to meet the demands of the automotive industry can be a bottleneck, requiring significant investment in infrastructure and skilled labor. Furthermore, repair and end-of-life management present challenges. The composite nature of many honeycomb structures can make them difficult to repair in case of minor damage, often necessitating replacement. Developing efficient and cost-effective recycling processes for composite honeycomb materials is an ongoing area of research and development, and the current lack of widespread infrastructure for this can be a concern for manufacturers focused on circular economy principles. Finally, established supply chains and industry inertia also play a role. The automotive industry has long-established supply chains and manufacturing processes built around traditional materials. Shifting to new materials like honeycomb sandwich composites requires significant retooling, training, and a willingness from all stakeholders in the supply chain to adapt.

The Composites segment is poised for significant dominance in the honeycomb sandwich for automotive market, driven by its exceptional properties and versatility. Composites, including carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), offer an unparalleled combination of lightweighting, high strength, stiffness, and corrosion resistance. This makes them the material of choice for applications where performance and weight reduction are paramount, such as in performance vehicles and electric vehicles where range optimization is critical. The ability to tailor the composite layup and resin system allows for precise control over mechanical properties, enabling engineers to design highly optimized components. For example, in Electric Vehicles, composite honeycomb sandwich panels are increasingly being used for battery enclosures, providing superior protection against impact and thermal runaway while significantly reducing the overall weight of the vehicle. This contributes directly to extended driving range and improved energy efficiency. Beyond EVs, composite honeycomb structures find application in structural components like chassis parts, body panels, and interior elements, offering substantial weight savings compared to their metal counterparts. The ongoing advancements in composite manufacturing technologies, such as automated tape laying (ATL) and automated fiber placement (AFP), are also making composite honeycomb structures more cost-effective and scalable for automotive production. This increasing accessibility, coupled with their inherent performance advantages, solidifies the dominance of the composites segment.

Among the applications, the Electric Vehicle (EV) segment is expected to be the primary driver of growth and market dominance for honeycomb sandwich materials. The fundamental design and operational requirements of EVs inherently favor lightweight, high-strength materials. The critical need to maximize battery range necessitates aggressive weight reduction strategies across the entire vehicle architecture. Honeycomb sandwich structures, with their exceptional strength-to-weight ratio, are ideally suited for this purpose. They are being increasingly integrated into battery pack enclosures, providing robust protection against impact and thermal events while minimizing added weight. Furthermore, they are employed in structural components, interior panels, and even in the body-in-white, contributing to overall vehicle rigidity and crashworthiness without compromising efficiency. The growing global demand for EVs, spurred by government regulations, environmental concerns, and technological advancements, directly translates into a burgeoning market for advanced materials that can enhance EV performance. As battery technology continues to evolve and charging infrastructure expands, the demand for lighter, more efficient EVs will only intensify, further solidifying the dominance of the EV application segment for honeycomb sandwich materials. The inherent safety benefits of honeycomb structures in protecting sensitive battery components in the event of a collision are also a significant selling point, aligning with the industry's unwavering commitment to passenger safety.

Regionally, Asia Pacific is projected to emerge as a dominant market for honeycomb sandwich materials in the automotive sector. This dominance is attributed to several key factors:

The synergy of these factors positions Asia Pacific as the epicenter for the growth and adoption of honeycomb sandwich materials in the automotive industry, particularly within the burgeoning Electric Vehicle segment.

Several key factors are acting as significant catalysts for the growth of the honeycomb sandwich for automotive industry. The most prominent is the unwavering global push towards electrification of the automotive sector. As electric vehicles become mainstream, the demand for lightweighting to maximize battery range becomes paramount, directly benefiting honeycomb composites. Furthermore, the increasing stringency of global fuel efficiency and emissions regulations is compelling automakers to adopt lighter materials to meet compliance targets. Advancements in manufacturing technologies, leading to more cost-effective and scalable production of honeycomb structures, are also a critical growth catalyst. Finally, the growing awareness and demand for sustainable and eco-friendly transportation solutions further boost the appeal of advanced composite materials, including honeycomb sandwich structures.

This comprehensive report offers a deep dive into the Honeycomb Sandwich for Automotive market, providing unparalleled insights for industry stakeholders. It meticulously analyzes market size in millions of units, detailing growth trends across various Segments, including Type (Aluminum, Steel, Composites, Others) and Application (Electric Vehicle, Fuel Vehicle). The report scrutinizes Industry Developments, offering a forward-looking perspective on technological advancements and market dynamics. With a robust Study Period (2019-2033), encompassing the Historical Period (2019-2024), Base Year (2025), and an extensive Forecast Period (2025-2033), it delivers actionable intelligence for strategic decision-making. This report is an indispensable resource for manufacturers, suppliers, investors, and researchers seeking to navigate and capitalize on the evolving opportunities within this critical automotive materials sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 7.2% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 7.2%.

Key companies in the market include Benecor, EconCore N.V., Encocam, Hexcel Corporation, HONYLITE PVT, Foshan Liming Honeycomb Composite Material, Pacific Panels, Samia Canada, Schweiter Technologies, The Gill Corporation, .

The market segments include Type, Application.

The market size is estimated to be USD 701.7 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Honeycomb Sandwich for Automotive," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Honeycomb Sandwich for Automotive, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.