1. What is the projected Compound Annual Growth Rate (CAGR) of the High Efficiency Refining Agent?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

High Efficiency Refining Agent

High Efficiency Refining AgentHigh Efficiency Refining Agent by Type (Powder Flux, Granular Flux, World High Efficiency Refining Agent Production ), by Application (Aluminum Alloy Smelting, Pure Aluminum Smelting, World High Efficiency Refining Agent Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

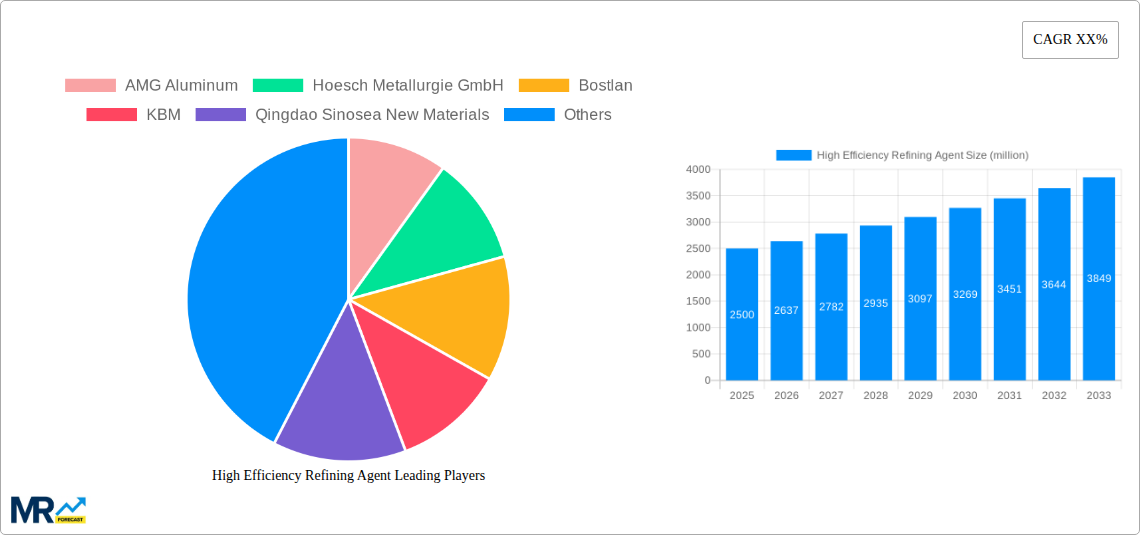

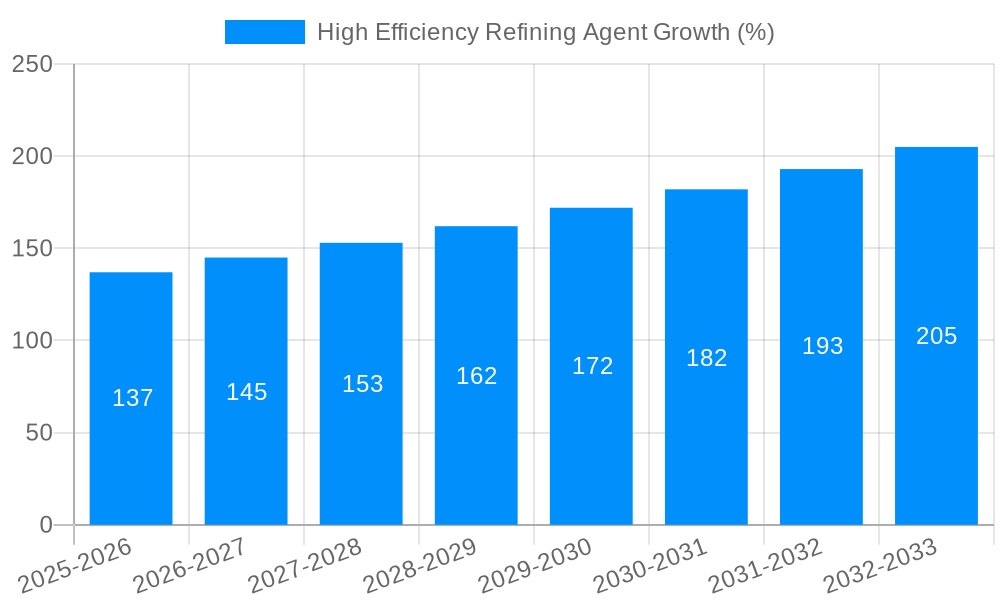

The global High Efficiency Refining Agent market is poised for significant expansion, projected to reach an estimated market size of approximately $2,500 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of around 5.5% anticipated to persist through 2033. This growth is primarily fueled by the escalating demand for high-purity aluminum across various industries, including automotive, aerospace, and electronics. The increasing production of aluminum alloys, essential for lightweighting in transportation and advanced manufacturing, directly correlates with the consumption of refining agents to enhance metal quality and reduce impurities. Furthermore, the ongoing pursuit of energy efficiency and improved casting processes within the aluminum smelting sector necessitates the adoption of advanced refining technologies, thereby driving market expansion. The shift towards sustainable manufacturing practices and the circular economy also plays a role, as efficient refining processes contribute to resource optimization and waste reduction in aluminum production.

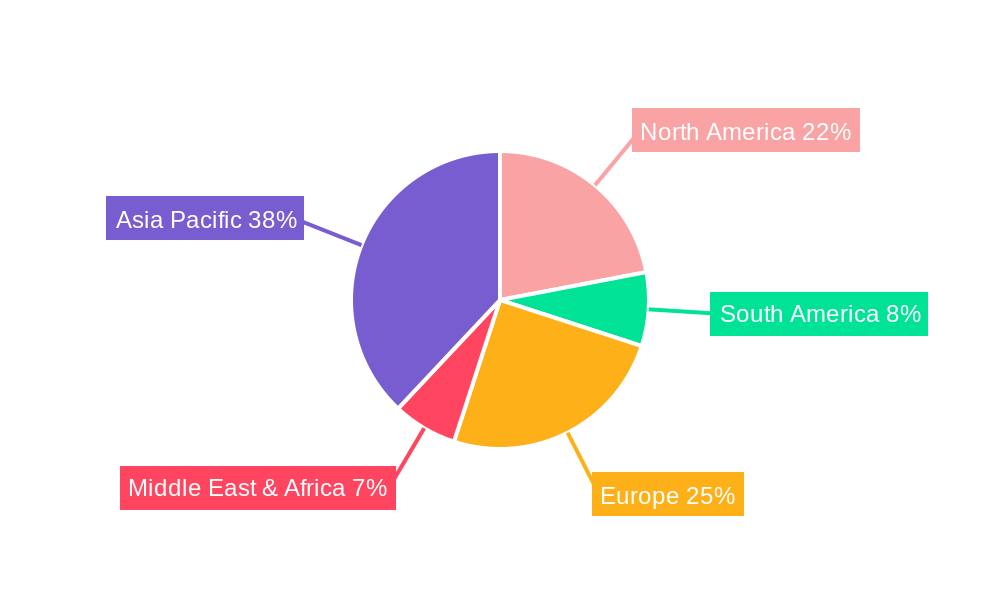

The market is broadly segmented into Powder Flux and Granular Flux types, with both finding extensive application in aluminum alloy smelting and pure aluminum smelting. While specific market shares for each segment are not explicitly detailed, the overall trend indicates a preference for agents that offer superior performance, cost-effectiveness, and environmental compatibility. Geographically, the Asia Pacific region, led by China, is expected to dominate the market due to its substantial aluminum production capacity and rapid industrialization. North America and Europe also represent significant markets, driven by their established automotive and aerospace industries. Key market restraints include the fluctuating prices of raw materials used in refining agents and the stringent environmental regulations that necessitate continuous innovation and investment in cleaner production technologies. However, the continuous technological advancements in refining agent formulations and the increasing focus on specialized applications are expected to overcome these challenges, ensuring sustained market growth.

The global high efficiency refining agent market is poised for significant expansion driven by the insatiable demand for superior quality aluminum products across diverse industrial applications. The study period, spanning from 2019 to 2033, with a base and estimated year of 2025 and a forecast period of 2025-2033, highlights a dynamic evolution. During the historical period (2019-2024), the market witnessed steady growth, fueled by advancements in aluminum smelting technologies and an increasing awareness of the benefits associated with refined aluminum, such as improved mechanical properties, enhanced surface finish, and reduced porosity. The projected trajectory for the market indicates a robust CAGR, suggesting that by 2025, global production is expected to reach approximately 400 million units, a figure that is set to climb substantially by the end of the forecast period. This growth is intrinsically linked to the burgeoning automotive, aerospace, and construction sectors, where lightweight and high-strength aluminum alloys are becoming indispensable. For instance, in the automotive industry, the push for fuel efficiency and reduced emissions necessitates the adoption of lighter materials, with aluminum alloys playing a pivotal role. Similarly, the aerospace sector relies on aluminum for its exceptional strength-to-weight ratio. The construction industry benefits from aluminum's corrosion resistance and aesthetic appeal. Furthermore, the increasing emphasis on recycling and sustainability within the aluminum industry further bolsters the demand for high efficiency refining agents, as they are crucial for treating recycled aluminum to meet stringent quality standards. The development of novel refining agent formulations, offering improved efficiency and reduced environmental impact, will be a key trend shaping the market landscape. Innovations in granular flux formulations, designed for easier handling and precise dosing in automated smelting processes, are gaining traction. The market is also observing a growing preference for powder fluxes that offer superior dispersion and reactivity, leading to more effective removal of impurities and gas entrapment. As the world's leading manufacturers continue to innovate and expand their production capacities, the global supply chain for high efficiency refining agents will solidify, ensuring a consistent availability of these critical materials to meet the escalating global demand. The market's expansion is not just about volume but also about the increasing sophistication of the refining agents themselves, incorporating advanced chemical compositions and physical properties to address the nuanced requirements of different aluminum alloys and smelting processes.

Several potent forces are converging to propel the global high efficiency refining agent market forward. Foremost among these is the relentless demand for high-quality aluminum products, driven by the ever-expanding needs of industries such as automotive, aerospace, and construction. These sectors require aluminum with superior mechanical properties, excellent surface finish, and minimal porosity for applications where performance and reliability are paramount. The growing global emphasis on sustainability and the circular economy is another significant driver. As the world strives to reduce its carbon footprint, the recycling of aluminum is becoming increasingly critical. High efficiency refining agents are indispensable in the remelting and refining of scrap aluminum, enabling it to meet the stringent quality standards required for new product manufacturing. This not only conserves energy and resources but also significantly reduces the environmental impact associated with primary aluminum production. Furthermore, technological advancements in aluminum smelting processes are creating new opportunities. Innovations in furnace design, casting technologies, and process automation are leading to the adoption of more sophisticated refining agents that can optimize these advanced operations. The development of novel formulations, offering enhanced impurity removal, gas scavenging, and grain refinement capabilities, is directly addressing the evolving needs of aluminum producers worldwide. The increasing global aluminum production capacity, particularly in emerging economies, further fuels this demand. As more aluminum is produced and recycled, the consumption of refining agents naturally escalates. The quest for lighter, stronger, and more fuel-efficient vehicles in the automotive sector, coupled with the stringent safety requirements in aerospace, continues to underscore the importance of high-performance aluminum alloys, thereby directly boosting the demand for effective refining agents.

Despite the promising growth trajectory, the high efficiency refining agent market is not without its hurdles. One of the primary challenges is the stringent regulatory environment surrounding chemical usage, particularly concerning environmental impact and worker safety. Manufacturers must adhere to evolving regulations, which can necessitate significant investments in research and development for greener formulations and safer handling practices. Fluctuations in the price of raw materials, such as alkali metals and other key chemical components used in refining agents, can also pose a significant restraint. Volatility in these input costs can directly impact the profitability of refining agent producers and, consequently, the pricing for end-users. Another challenge lies in the technical expertise required for the optimal application of these agents. Improper usage can lead to suboptimal results, increased costs, and potential quality issues in the final aluminum product. This necessitates comprehensive training and support for end-users, which can be a resource-intensive undertaking for manufacturers. The market also faces competition from alternative refining technologies and processes, although high efficiency refining agents remain the dominant solution for many applications. Furthermore, the global economic landscape, with its inherent uncertainties and potential for slowdowns, can indirectly affect the demand for aluminum and, by extension, the consumption of refining agents. The capital expenditure required for upgrading existing smelting facilities to incorporate advanced refining techniques can also be a barrier for some smaller producers, thus limiting the widespread adoption of the most advanced refining agent solutions.

The dominance within the global high efficiency refining agent market is a multifaceted phenomenon, influenced by both regional manufacturing prowess and specific product segment strengths.

Key Regions and Countries:

Dominant Segments:

The interplay between strong regional manufacturing hubs and the critical applications and types of refining agents creates a dynamic market where growth is concentrated and driven by specific industrial needs and technological advancements.

The high efficiency refining agent industry is experiencing significant growth catalysts, primarily driven by the escalating demand for high-performance aluminum across key sectors. The automotive industry's relentless pursuit of lightweighting for improved fuel efficiency and reduced emissions is a major impetus, as aluminum alloys are essential for achieving these goals. Similarly, the aerospace sector's requirement for strong, lightweight materials in aircraft construction directly fuels the need for superior aluminum refining. Furthermore, the global surge in aluminum recycling initiatives is a powerful growth catalyst. High efficiency refining agents are indispensable for treating recycled aluminum scrap to meet stringent quality standards, thereby promoting a circular economy and reducing reliance on primary production. Technological advancements in smelting processes also act as catalysts, necessitating the development and adoption of more advanced refining agents that can optimize these evolving operations.

This comprehensive report delves into the intricate landscape of the High Efficiency Refining Agent market, providing an in-depth analysis of its trends, drivers, challenges, and future prospects. With a meticulous study period spanning from 2019 to 2033, and a base year of 2025, the report offers valuable insights into the market dynamics. It highlights key industry developments, crucial growth catalysts, and identifies the leading players shaping the sector. The analysis encompasses a granular examination of market segments, including types of refining agents (Powder Flux, Granular Flux) and their critical applications in Aluminum Alloy Smelting and Pure Aluminum Smelting. The report also provides a detailed outlook on World High Efficiency Refining Agent Production, projecting significant growth in the coming years, with estimated production reaching approximately 400 million units by 2025 and continuing its upward trajectory through 2033. This exhaustive coverage equips stakeholders with the knowledge necessary to navigate and capitalize on opportunities within this vital industrial market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include AMG Aluminum, Hoesch Metallurgie GmbH, Bostlan, KBM, Qingdao Sinosea New Materials, Xuzhou Zhengbang Aluminum Industry, Foshan Jilida Aluminum Technology, Xuzhou Lige Metal Material, Xuzhou Huazhong Aluminium, Jiangsu Huajia Aluminum Technology, Xuzhou Jinlong Aluminum Industry, Xuzhou Hudeng Metal Material, Nantong Anshen Metal Meterials, JINTAI Group, Sichuan Lande Industry, Xuzhou Ruichi Metal Meterials, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "High Efficiency Refining Agent," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the High Efficiency Refining Agent, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.