1. What is the projected Compound Annual Growth Rate (CAGR) of the Glass Tube Injection Bottle?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Glass Tube Injection Bottle

Glass Tube Injection BottleGlass Tube Injection Bottle by Type (Soda-lime Glass Tube Injection Bottle, Low Borosilicate Glass Tube Injection Bottle, Medium Borosilicate Glass Tube Injection Bottle, High Borosilicate Glass Tube Injection Bottle), by Application (Hospitals, Clinics, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

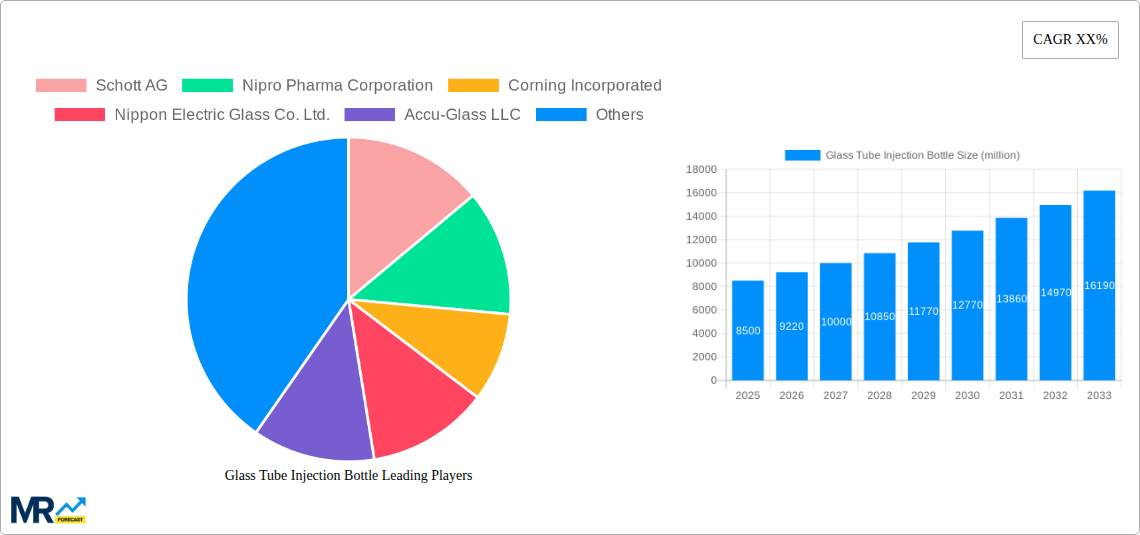

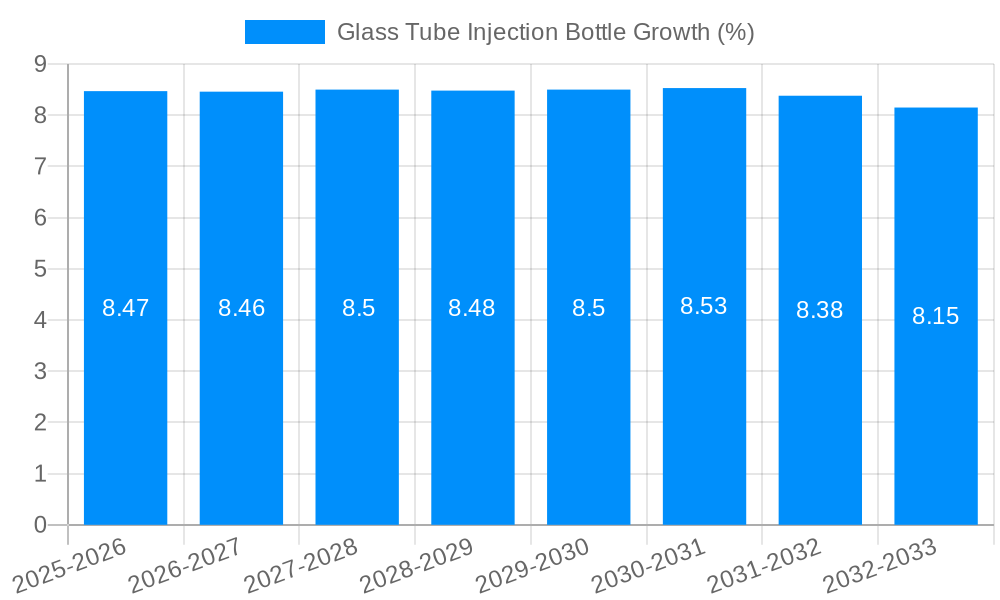

The global Glass Tube Injection Bottle market is poised for significant expansion, projected to reach a robust USD 15,000 million by 2033, driven by a Compound Annual Growth Rate (CAGR) of 8.5% from 2025 to 2033. This growth is primarily fueled by the escalating demand for parenteral drug delivery systems, propelled by the increasing prevalence of chronic diseases and the continuous development of novel biopharmaceuticals. The rising healthcare expenditures worldwide, coupled with advancements in sterile manufacturing techniques, further bolster the market's upward trajectory. The shift towards single-dose vials and pre-filled syringes, offering enhanced patient convenience and reduced medication errors, is a key trend influencing product innovation and market dynamics. Furthermore, the growing emphasis on drug stability and product integrity is driving the adoption of high-quality glass tubing, particularly borosilicate variants, which offer superior chemical resistance and thermal shock endurance.

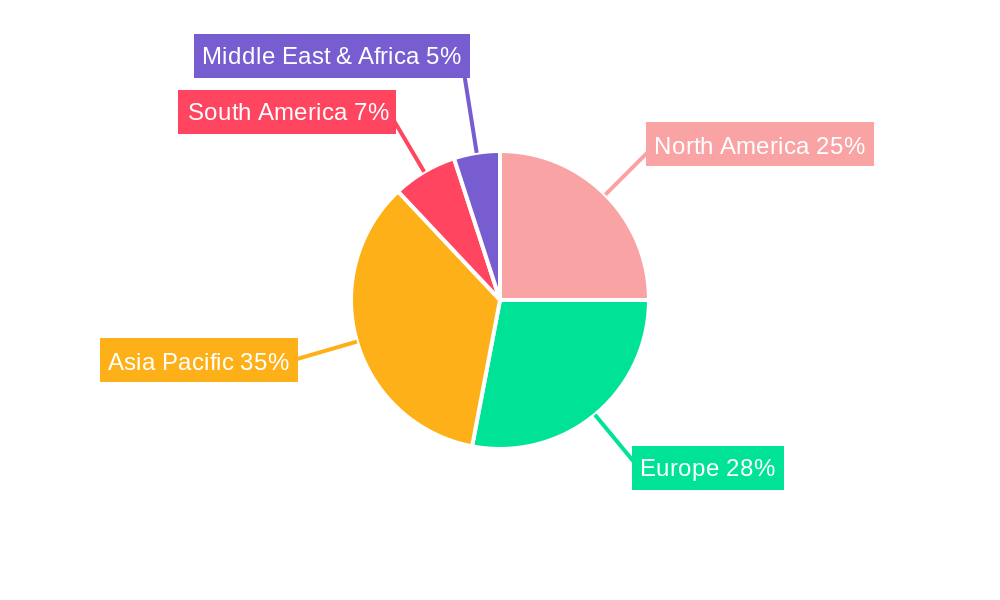

The market's segmentation reveals distinct growth patterns across various types and applications. Low borosilicate and medium borosilicate glass tube injection bottles are expected to witness substantial demand due to their cost-effectiveness and broad applicability in pharmaceuticals and vaccines. However, high borosilicate glass tube injection bottles are anticipated to see accelerated growth, driven by the stringent requirements of complex biologics and sensitive drug formulations. Hospitals remain the dominant application segment, owing to their high volume of parenteral drug administration. Clinics are also emerging as a significant growth area, reflecting the decentralization of healthcare services. Geographically, the Asia Pacific region is expected to lead the market in terms of growth, spurred by its large population, expanding healthcare infrastructure, and increasing domestic pharmaceutical production. North America and Europe will continue to be mature markets with sustained demand for premium glass tube injection bottles, driven by advanced healthcare systems and strong R&D activities. While the market exhibits strong growth potential, restraints such as fluctuating raw material prices and intense competition from alternative packaging materials need to be navigated strategically by market players.

This report delves into the dynamic global Glass Tube Injection Bottle market, providing an exhaustive analysis spanning from the historical period of 2019-2024 to a projected forecast up to 2033. The study meticulously examines market trends, driving forces, challenges, key regional and segmental insights, growth catalysts, and leading industry players. With the Base Year set at 2025, the report offers a granular understanding of market dynamics, equipping stakeholders with critical data to navigate this evolving landscape. The Estimated Year also standing at 2025 allows for immediate actionable insights. This comprehensive research is invaluable for manufacturers, suppliers, investors, and regulatory bodies seeking to understand the present state and future trajectory of the glass tube injection bottle industry.

The global Glass Tube Injection Bottle market is experiencing a period of robust expansion, driven by escalating healthcare expenditures and the burgeoning pharmaceutical industry worldwide. This growth is underscored by a projected market valuation that is expected to reach US$ 5,500 million by the end of the forecast period in 2033, a significant increase from its historical performance. The increasing demand for sterile and inert packaging solutions for parenteral drugs, vaccines, and sensitive biologics is a primary catalyst. High Borosilicate Glass Tube Injection Bottles are particularly gaining traction due to their superior chemical resistance and thermal stability, making them ideal for storing a wide range of pharmaceutical formulations, including those requiring high-temperature sterilization. The market is also witnessing a trend towards specialized designs, catering to specific drug delivery systems and therapeutic areas. Innovations in glass manufacturing, focusing on enhanced purity and reduced leachables, are also shaping the market, ensuring product integrity and patient safety. Furthermore, the growing emphasis on single-use vials, driven by infection control protocols and the need for accurate dosing, is further bolstering the demand for glass tube injection bottles. The market's trajectory also reflects a conscious shift towards sustainable and recyclable packaging materials, with glass being a prime contender in this regard. The increasing prevalence of chronic diseases, leading to a higher demand for injectable medications, is also a key factor contributing to the sustained growth of this market. Emerging economies, with their expanding healthcare infrastructure and rising disposable incomes, are presenting significant growth opportunities for market players. The report also highlights a growing preference for pre-filled syringes, which indirectly fuels the demand for high-quality glass tubes used in their manufacturing. The intricate interplay of technological advancements, regulatory compliances, and evolving healthcare needs will continue to define the market's landscape in the coming years, ensuring its continued upward trajectory. The market is projected to witness a Compound Annual Growth Rate (CAGR) of approximately 4.2% during the forecast period.

Several powerful forces are collectively propelling the growth of the Glass Tube Injection Bottle market. The increasing global demand for pharmaceuticals and biologics, particularly for injectable formulations, is a paramount driver. The escalating prevalence of chronic diseases such as diabetes, cardiovascular ailments, and cancer necessitates a consistent supply of injectable medications, directly translating into higher demand for reliable and sterile packaging. Furthermore, the advancements in biopharmaceutical development and the rise of personalized medicine are creating a need for specialized packaging that can maintain the stability and efficacy of complex and sensitive drug molecules. The inherent advantages of glass as a packaging material – its inertness, impermeability, and ability to withstand sterilization processes – make it the preferred choice for these high-value therapeutics. The growing emphasis on patient safety and drug integrity further solidifies the market position of glass tube injection bottles. Unlike plastics, glass is non-reactive and does not leach harmful chemicals into the drug, ensuring that the therapeutic effect remains uncompromised. Moreover, the supportive regulatory landscape that often mandates the use of high-quality packaging for injectable drugs also contributes to the market's expansion. The increasing focus on infection control and the prevention of cross-contamination in healthcare settings is also driving the adoption of sterile, single-use glass vials.

Despite the promising growth trajectory, the Glass Tube Injection Bottle market is not without its inherent challenges and restraints. The inherent fragility of glass poses a significant logistical hurdle. During transportation and handling, there is a perpetual risk of breakage, leading to product loss and increased costs. This necessitates stringent packaging and careful handling protocols throughout the supply chain. Another considerable restraint is the higher cost of production compared to plastic alternatives. The manufacturing processes for glass vials are more energy-intensive and require specialized equipment, which can translate into higher unit costs, potentially impacting the affordability of medications, especially in price-sensitive markets. Furthermore, growing competition from alternative packaging materials, particularly advanced plastics and polymers, presents a continuous challenge. While glass offers superior inertness, some plastic alternatives are becoming increasingly sophisticated in their barrier properties and may offer advantages in terms of weight and cost. The strict regulatory requirements and quality control standards in the pharmaceutical industry, while beneficial for ensuring product safety, also add to the complexity and cost of manufacturing, requiring significant investment in quality assurance and compliance. Fluctuations in raw material prices, particularly for silica sand, a key component in glass manufacturing, can also impact profit margins. Finally, environmental concerns regarding the energy consumption during glass production and disposal, although glass is recyclable, can sometimes lead to scrutiny and a push for more sustainable alternatives.

The global Glass Tube Injection Bottle market is characterized by diverse regional strengths and segment preferences. However, based on current trends and projected growth, North America and Europe are poised to remain dominant regions, primarily due to their advanced healthcare infrastructures, high pharmaceutical R&D investments, and stringent quality standards. The presence of major pharmaceutical and biotechnology companies in these regions fuels a consistent demand for high-quality glass tube injection bottles for a wide array of therapeutic applications.

Within these leading regions, and indeed globally, the High Borosilicate Glass Tube Injection Bottle segment is expected to exhibit the most significant dominance. This is directly linked to the increasing production of complex and sensitive biologics and biosimilars. These advanced drug formulations often require packaging that offers exceptional chemical inertness, thermal shock resistance, and minimal interaction with the drug product. High borosilicate glass, with its superior performance characteristics, is the material of choice for preserving the integrity and efficacy of such high-value medications. The projected market size for this segment alone is estimated to exceed US$ 2,500 million by 2033.

In terms of application, Hospitals will continue to be the largest end-user segment, driven by the widespread use of injectable drugs for patient treatment and post-operative care. The sheer volume of pharmaceutical administrations within hospital settings ensures a perpetual demand for reliable and sterile injection bottles. The market size for the Hospitals segment is projected to reach approximately US$ 3,000 million by 2033.

Furthermore, the Clinics segment is also anticipated to witness substantial growth, fueled by the expansion of outpatient services and the increasing accessibility of healthcare in developing economies. As more medical procedures and treatments are shifted to outpatient settings, the demand for injectable medications and consequently glass tube injection bottles in clinics will rise proportionally.

The "Others" segment, which encompasses research laboratories, veterinary applications, and specialized medical device manufacturers, also contributes significantly to the market's overall size, with an estimated market value of US$ 1,000 million by 2033, showcasing the diverse applications of these essential pharmaceutical packaging components. The demand for Low Borosilicate Glass Tube Injection Bottles will continue to be steady for less sensitive formulations and certain vaccines, contributing a considerable portion to the overall market value, estimated at around US$ 500 million.

Several key growth catalysts are fueling the expansion of the Glass Tube Injection Bottle industry. The relentless rise in the global burden of chronic diseases and infectious diseases necessitates an ever-increasing supply of injectable pharmaceuticals, directly boosting the demand for these essential packaging components. The rapid advancements in biotechnology and the development of novel biologic drugs and vaccines are also significant drivers, as these sensitive formulations often require the inertness and sterility that glass provides. Furthermore, growing investments in pharmaceutical R&D, particularly in emerging economies, are creating new markets and opportunities for glass tube injection bottle manufacturers.

This report offers an all-encompassing view of the Glass Tube Injection Bottle market, providing in-depth insights into its multifaceted dynamics. Beyond the statistical projections, the report meticulously analyzes the intricate interplay of technological advancements, regulatory landscapes, and evolving market demands. It offers a granular breakdown of segment-specific trends, regional market penetrations, and the strategic initiatives of key industry players. Stakeholders can leverage this report to identify untapped opportunities, mitigate potential risks, and formulate robust business strategies. The research methodology employed ensures data accuracy and a forward-looking perspective, making this report an indispensable resource for anyone involved in the pharmaceutical packaging ecosystem.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Schott AG, Nipro Pharma Corporation, Corning Incorporated, Nippon Electric Glass Co. Ltd., Accu-Glass LLC, Origin, Gerresheimer, DWK Life Sciences, Bormioli Pharma, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Glass Tube Injection Bottle," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Glass Tube Injection Bottle, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.