1. What is the projected Compound Annual Growth Rate (CAGR) of the Freeze Dryer Automatic Loading And Unloading Systems?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Freeze Dryer Automatic Loading And Unloading Systems

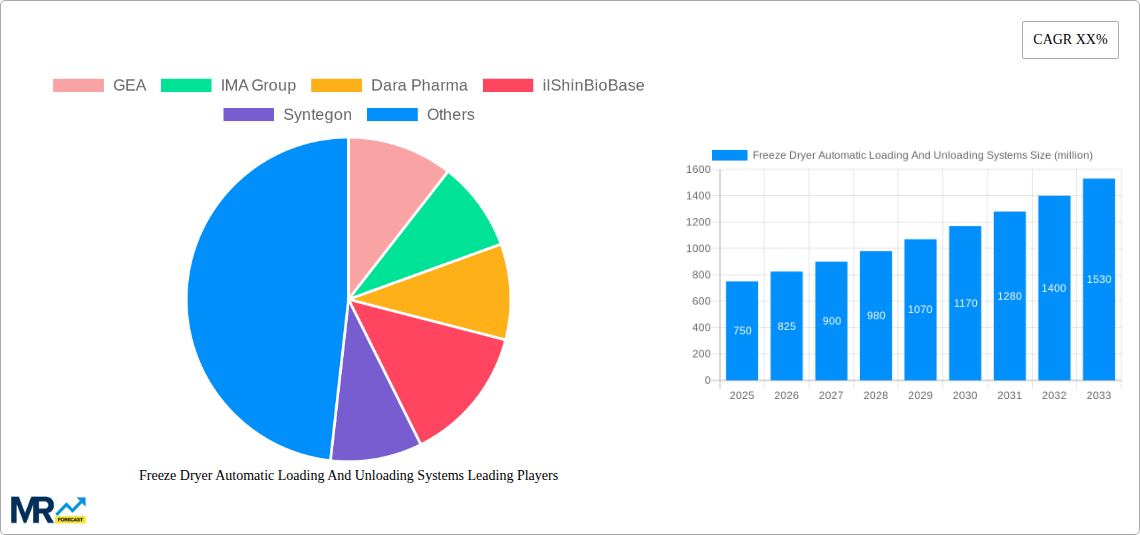

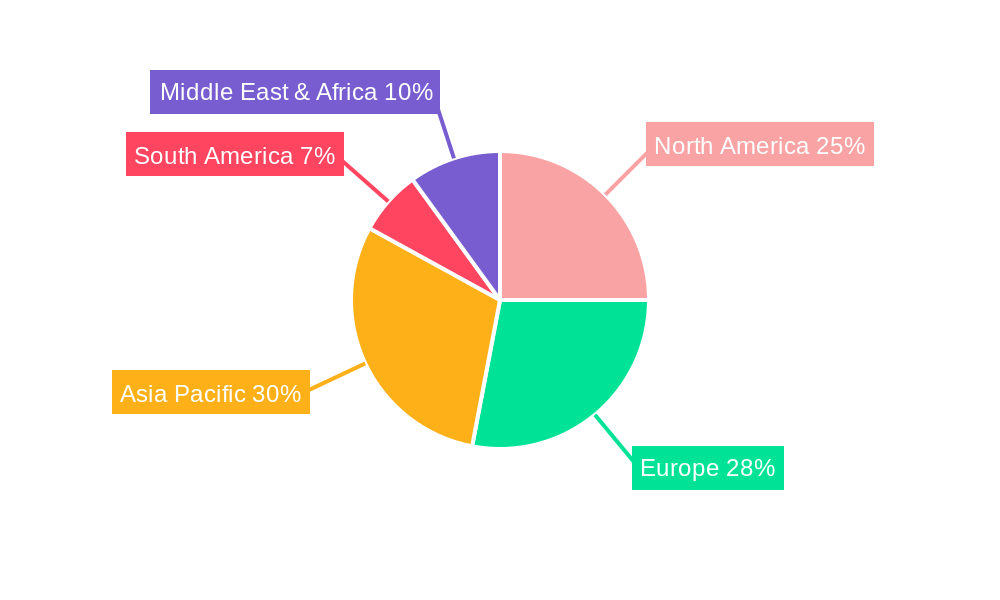

Freeze Dryer Automatic Loading And Unloading SystemsFreeze Dryer Automatic Loading And Unloading Systems by Type (Fully Automatic, Semi-Automatic, World Freeze Dryer Automatic Loading And Unloading Systems Production ), by Application (Pharmaceutical, Food, Others, World Freeze Dryer Automatic Loading And Unloading Systems Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

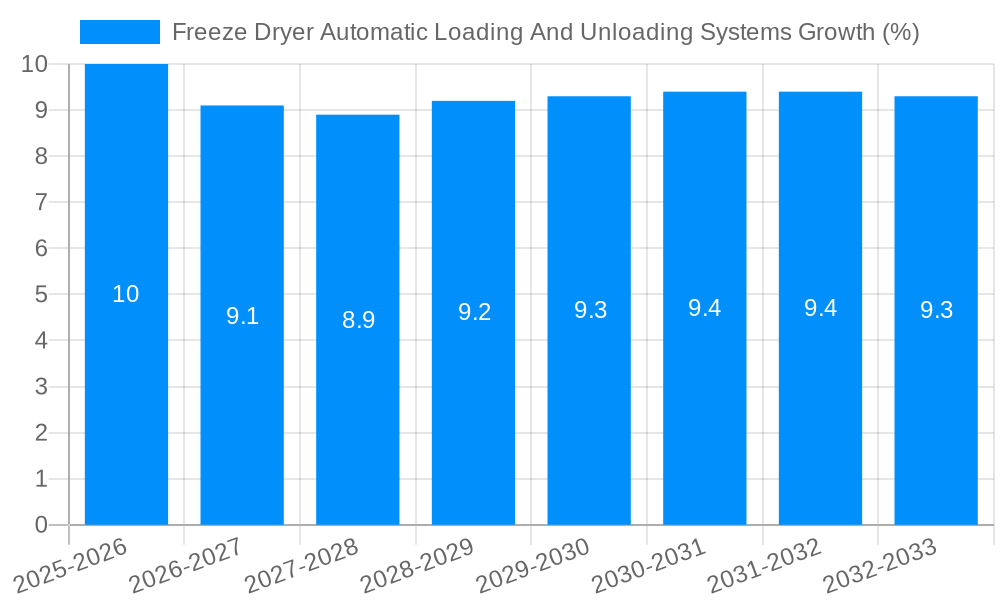

The global market for Freeze Dryer Automatic Loading and Unloading Systems is experiencing robust expansion, projected to reach an estimated USD XXX million in 2025 and grow at a Compound Annual Growth Rate (CAGR) of XX% through 2033. This significant growth is primarily fueled by the increasing demand for sterile and shelf-stable pharmaceutical products, coupled with the expanding applications of freeze-drying technology in the food industry for preserving quality and extending shelf life. The pharmaceutical sector, a dominant application segment, benefits immensely from the enhanced efficiency, reduced contamination risks, and improved product integrity offered by automated loading and unloading solutions. This drives significant investment in advanced automation for lyophilization processes, particularly in the production of vaccines, biologics, and complex drug formulations. The growing emphasis on stringent regulatory compliance and the need for streamlined manufacturing operations further bolster the adoption of these sophisticated systems.

The market is characterized by key trends such as the rise of fully automatic systems offering seamless integration with upstream and downstream processes, significantly minimizing manual intervention and human error. Innovations in robotics and intelligent control systems are enhancing precision and throughput, while specialized solutions for aseptic environments are becoming increasingly critical. Restraints, though present, are largely being overcome by technological advancements. High initial investment costs for sophisticated automated systems can be a hurdle for smaller manufacturers, but the long-term benefits of increased productivity and reduced operational expenses often outweigh this. The complex validation processes for pharmaceutical manufacturing can also present challenges. However, the overarching drivers of technological innovation, growing pharmaceutical and food processing needs, and a global push for enhanced manufacturing efficiency are set to propel the market for freeze dryer automatic loading and unloading systems to new heights.

This report delves into the dynamic global market for Freeze Dryer Automatic Loading and Unloading Systems, offering a detailed analysis of trends, drivers, challenges, and growth opportunities. The study spans the historical period of 2019-2024, with a base year of 2025 and extends to a comprehensive forecast period of 2025-2033. The market is projected to witness significant expansion, driven by increasing demand for efficiency and sterility in pharmaceutical and food processing. Our research incorporates insights from key industry players and a granular examination of various market segments, providing a robust understanding of the competitive landscape and future trajectory. The estimated market value in 2025 is projected to be in the range of $2,500 million, with substantial growth anticipated over the forecast period.

The global market for Freeze Dryer Automatic Loading and Unloading Systems is experiencing a profound transformation, driven by an escalating need for enhanced operational efficiency, reduced contamination risks, and improved product quality across critical industries such as pharmaceuticals and food processing. Over the Study Period (2019-2033), a significant trend has been the continuous advancement and adoption of Fully Automatic systems. These sophisticated solutions, capable of executing complex loading and unloading sequences with minimal human intervention, are becoming the benchmark for high-throughput operations. The increasing complexity of biopharmaceutical products, including vaccines, antibodies, and cell and gene therapies, necessitates stringent aseptic conditions, which fully automated systems are ideally positioned to provide. This shift is not merely about automation; it's about ensuring sterility assurance levels (SALs) that are paramount in these sensitive applications. Furthermore, the integration of advanced robotics, sophisticated vision systems for precise product placement, and intelligent software for process control are defining new paradigms in this sector. The market is witnessing a substantial increase in investments towards developing these integrated solutions. The World Freeze Dryer Automatic Loading and Unloading Systems Production is projected to grow, reflecting this heightened demand.

The pharmaceutical segment continues to lead the charge in adopting these advanced systems. The stringent regulatory requirements, the high value of biologics, and the imperative to minimize batch failures are powerful motivators for investing in automation. Companies are increasingly looking for solutions that not only automate the process but also provide comprehensive data logging and traceability for regulatory compliance. The food industry, while historically a strong adopter of semi-automatic systems, is also showing a growing interest in fully automated solutions, particularly for high-value or specialized food products where preservation of quality and extended shelf life are critical. Innovations in tray handling, vial capping, and sterile transfer technologies are further fueling market growth. The trend towards Industry 4.0 principles, emphasizing connectivity, data analytics, and predictive maintenance, is also shaping the development of these systems, enabling more intelligent and responsive operations. The estimated market value for the World Freeze Dryer Automatic Loading and Unloading Systems Production in the Estimated Year (2025) is expected to be around $2,500 million. The forecast period (2025-2033) anticipates robust Compound Annual Growth Rates (CAGRs) as more manufacturers embrace these cutting-edge technologies.

The accelerating growth of the Freeze Dryer Automatic Loading and Unloading Systems market is predominantly propelled by the relentless pursuit of operational excellence and product integrity within the pharmaceutical and food industries. A primary driver is the ever-increasing demand for efficiency and throughput in manufacturing processes. As the global population grows and healthcare needs evolve, the production volumes of critical drugs, vaccines, and life-saving therapies are escalating. Automatic loading and unloading systems significantly reduce cycle times, minimize manual handling errors, and allow for continuous operation, thereby boosting overall manufacturing output. The pharmaceutical sector, in particular, benefits from these advancements due to the high-value nature of biologics and the imperative to deliver treatments to market faster.

Another significant propellant is the stringent regulatory landscape governing pharmaceutical manufacturing. Regulatory bodies worldwide impose rigorous standards for sterility assurance and contamination control. Automatic systems, by minimizing human intervention within the freeze-drying chamber, drastically reduce the risk of microbial contamination, ensuring aseptic processing and compliance with Good Manufacturing Practices (GMP). This is crucial for the production of sensitive biologics, vaccines, and sterile injectables, where even minor contamination can lead to product loss and severe health risks for patients. The growing emphasis on patient safety and product efficacy directly translates into a greater demand for robust and reliable automated loading and unloading solutions. This inherent need for sterile and controlled environments drives substantial investment in advanced automation technologies.

Despite the promising growth trajectory, the Freeze Dryer Automatic Loading and Unloading Systems market faces several significant challenges and restraints that can impact its widespread adoption and development. One of the primary hurdles is the high initial capital investment required for advanced automatic systems. These sophisticated robotic and automation solutions, particularly fully automatic ones, involve substantial upfront costs for purchase, installation, and integration with existing freeze-dryers and facility infrastructure. This can be a significant barrier for small to medium-sized enterprises (SMEs) or companies with limited capital budgets, especially in emerging markets, potentially slowing down the transition from manual or semi-automatic operations.

Furthermore, the complexity of integration and validation presents another considerable challenge. Integrating automatic loading and unloading systems with various freeze-dryer models and other upstream and downstream processing equipment requires specialized engineering expertise. The validation of these automated systems to meet stringent regulatory requirements, such as those from the FDA and EMA, is a time-consuming and resource-intensive process. Ensuring the reliability, accuracy, and sterility assurance of the entire automated workflow demands extensive testing and documentation, which can add to the overall project timeline and cost. The need for highly skilled personnel to operate, maintain, and troubleshoot these advanced systems also poses a challenge, as specialized training programs are essential but may not be readily available or adopted by all organizations.

The global Freeze Dryer Automatic Loading and Unloading Systems market is poised for significant growth, with certain regions and segments expected to take the lead. The Pharmaceutical segment is unequivocally set to dominate the market. This dominance stems from several interconnected factors inherent to drug manufacturing:

Geographically, North America and Europe are anticipated to remain the dominant regions in the Freeze Dryer Automatic Loading and Unloading Systems market throughout the Study Period (2019-2033).

North America (United States and Canada):

Europe (Germany, Switzerland, United Kingdom, France):

While Asia-Pacific is projected to exhibit the highest growth rate due to rapid expansion in its pharmaceutical and food processing sectors, North America and Europe will continue to command the largest market share owing to their mature industries and early adoption of advanced automation.

The Type: Fully Automatic segment is also projected to dominate in terms of value and growth. The increasing complexity of pharmaceutical products, the demand for sterility assurance, and the drive for maximum efficiency are propelling the adoption of fully automatic systems over their semi-automatic counterparts.

The World Freeze Dryer Automatic Loading and Unloading Systems Production is experiencing robust growth fueled by several key catalysts. The escalating demand for biologics and vaccines, especially in light of global health events, necessitates higher production volumes and stringent sterility controls. This drives investment in automated solutions to improve efficiency and minimize contamination risks. Furthermore, the pharmaceutical industry's continuous push for operational excellence and adherence to increasingly rigorous regulatory standards provides a strong impetus for adopting advanced automation to ensure product quality and patient safety. The ongoing advancements in robotics, artificial intelligence, and machine learning are enabling the development of more sophisticated and intelligent loading and unloading systems, further enhancing their appeal. The integration of these systems with broader digital manufacturing platforms (Industry 4.0) is also creating new avenues for optimization and data-driven decision-making, acting as a significant growth catalyst.

This comprehensive report provides an in-depth analysis of the global Freeze Dryer Automatic Loading and Unloading Systems market, encompassing key trends, driving forces, challenges, and future projections. The Study Period (2019-2033), with a Base Year of 2025, allows for a thorough understanding of market dynamics. The report highlights the significant role of the Pharmaceutical segment and the dominance of Fully Automatic systems, driven by stringent regulatory requirements and the growing demand for biologics. Geographically, North America and Europe are identified as leading regions. The report details growth catalysts, including technological advancements in robotics and AI, and the increasing need for operational efficiency. It also identifies key players and significant market developments, offering valuable insights for stakeholders to navigate this evolving landscape. The estimated market value in 2025 is projected to be $2,500 million.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include GEA, IMA Group, Dara Pharma, ilShinBioBase, Syntegon, Stäubli, ATS Life Sciences, Martin Christ, Telstar, SERAIL-TECH, AUSTAR Group, Optima, HOF Group, Triplepoint, ROTA, Biopharma Group, Findnovo, Rotech, Truking Technology, Shinva Medical Instrument, Shanghai East China Group Technology, Tofflon, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Freeze Dryer Automatic Loading And Unloading Systems," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Freeze Dryer Automatic Loading And Unloading Systems, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.