1. What is the projected Compound Annual Growth Rate (CAGR) of the Fe-based Nanocrystalline Alloy?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Fe-based Nanocrystalline Alloy

Fe-based Nanocrystalline AlloyFe-based Nanocrystalline Alloy by Type (Thickness: 14~18μm, Thickness: 18~22μm, Thickness: 22~26μm, Others), by Application (Aerospace, New Energy, Consumer Electronics, Medical, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

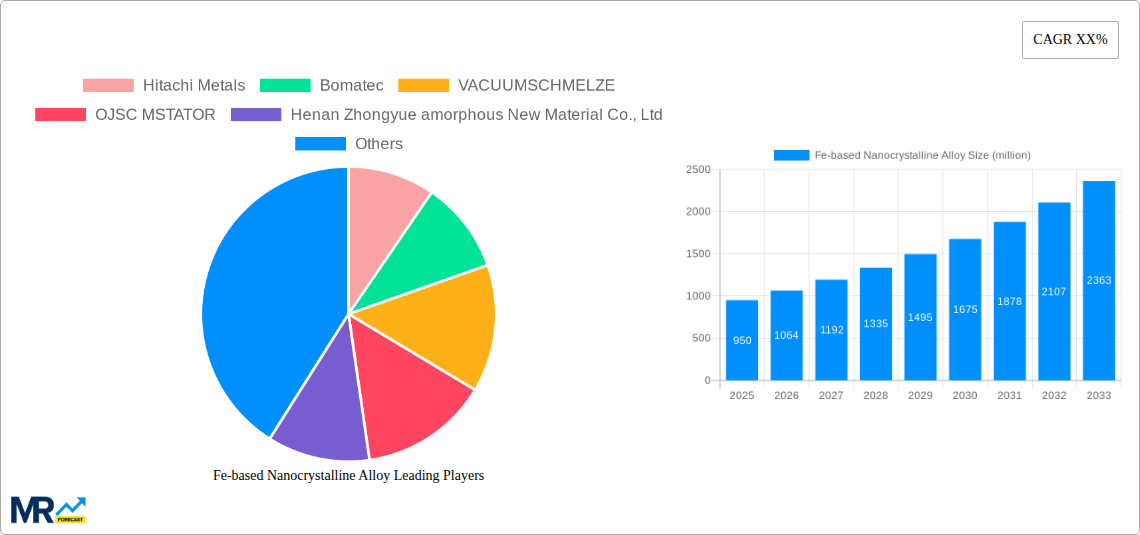

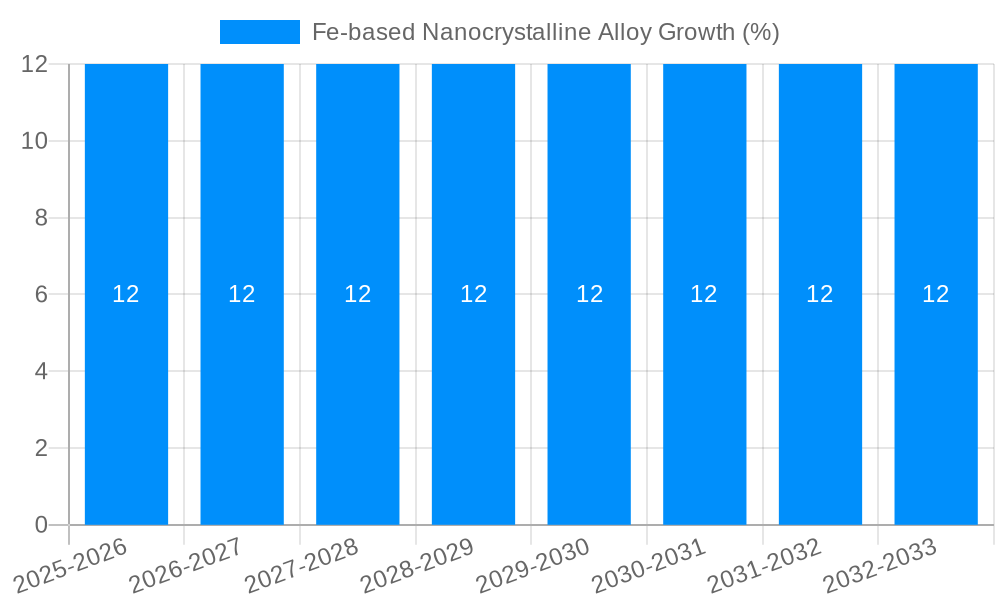

The global Fe-based Nanocrystalline Alloy market is poised for significant expansion, projected to reach an estimated market size of approximately $950 million by 2025, with a robust Compound Annual Growth Rate (CAGR) of around 12% anticipated throughout the forecast period of 2025-2033. This impressive growth is primarily fueled by the escalating demand for high-performance magnetic materials across burgeoning sectors. Key drivers include the rapid advancements in the aerospace industry, where these alloys are critical for lightweight and efficient components, and the burgeoning new energy sector, particularly in electric vehicles and renewable energy storage solutions. Furthermore, the increasing integration of these alloys in sophisticated consumer electronics and vital medical devices is contributing substantially to market momentum. The market is characterized by a segmentation based on thickness, with the 18-22µm and 22-26µm segments exhibiting strong adoption due to their optimal balance of magnetic properties and cost-effectiveness.

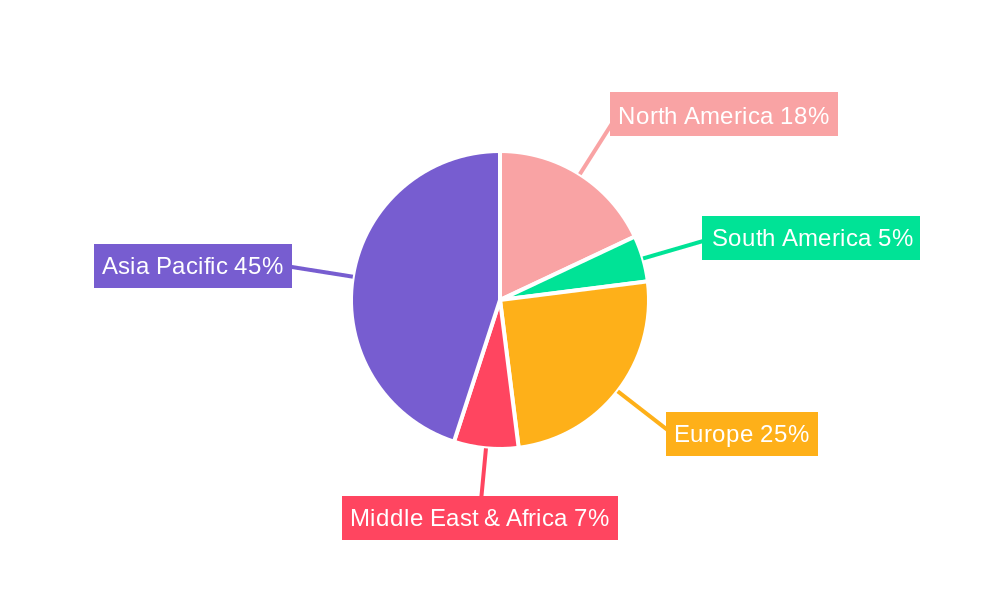

The market landscape is further shaped by critical trends such as the continuous innovation in alloy composition and manufacturing processes to enhance soft magnetic properties and reduce energy losses. There's a notable trend towards miniaturization and higher power density in electronic devices, creating a direct demand for advanced nanocrystalline materials. However, the market also faces certain restraints, including the relatively high initial investment costs associated with specialized manufacturing equipment and the need for stringent quality control to ensure performance consistency. Supply chain complexities and fluctuating raw material prices for key constituents like iron, silicon, and boron can also pose challenges. Despite these hurdles, the strategic importance of Fe-based Nanocrystalline Alloys in enabling next-generation technologies ensures sustained market growth, with Asia Pacific anticipated to lead in both production and consumption due to its strong manufacturing base and rapid technological adoption.

The global Fe-based nanocrystalline alloy market is poised for substantial expansion, with projections indicating a compound annual growth rate (CAGR) of approximately 7.5% from 2025 to 2033. This upward trajectory is underpinned by a confluence of technological advancements and escalating demand across various high-growth industries. The study period, spanning from 2019 to 2033, with a base year of 2025, highlights a robust historical performance during 2019-2024, setting a strong foundation for future growth. The market size, estimated to be in the million unit range by the base year of 2025, is expected to reach several hundred million units by the end of the forecast period. A significant driver for this growth is the inherent superiority of Fe-based nanocrystalline alloys over traditional soft magnetic materials. Their exceptional magnetic properties, including extremely low core loss, high saturation magnetization, and excellent frequency response, make them indispensable for optimizing energy efficiency and miniaturization in a wide array of electronic components.

The increasing integration of advanced power electronics, particularly in renewable energy systems and electric vehicles, is a critical factor fueling demand. As these sectors mature and expand, the need for highly efficient and compact magnetic cores becomes paramount. Furthermore, the relentless pursuit of enhanced performance and reduced energy consumption in consumer electronics, such as power adapters and inverters, is also contributing to market growth. Emerging applications in medical devices, where precision and reliability are non-negotiable, are also creating new avenues for Fe-based nanocrystalline alloys. The market's evolution is characterized by continuous innovation in alloy composition and manufacturing processes, aimed at further improving specific magnetic characteristics and tailoring them to niche applications. For instance, advancements in thin-film deposition techniques are enabling the production of even thinner and more flexible materials, opening doors for novel product designs and functionalities. The strategic focus by leading manufacturers on research and development will continue to shape the market, introducing new generations of alloys with superior performance metrics and broader applicability. The competitive landscape is becoming increasingly sophisticated, with companies vying for market share through product differentiation and strategic partnerships.

The Fe-based nanocrystalline alloy market is experiencing a powerful surge driven by several interconnected factors, primarily stemming from the global push for energy efficiency and the relentless advancement of electronic technologies. The escalating demand for electric vehicles (EVs) stands as a monumental driver. As governments worldwide implement stringent emission regulations and consumers embrace sustainable transportation, the need for high-performance power electronics in EVs, including inverters, converters, and onboard chargers, has exploded. Fe-based nanocrystalline alloys, with their superior core loss characteristics at high frequencies, are crucial for miniaturizing these components and improving the overall efficiency of EV powertrains. Simultaneously, the renewable energy sector, particularly solar and wind power, is witnessing unprecedented growth. The efficient conversion and transmission of electricity generated from these sources necessitate advanced power electronic components that can handle high power densities and operate with minimal energy dissipation. Fe-based nanocrystalline alloys are integral to the construction of inverters and transformers used in these applications, directly contributing to the grid's stability and reducing energy wastage. Beyond these major sectors, the continuous evolution of consumer electronics, which demands smaller, lighter, and more energy-efficient devices, also plays a significant role. From high-efficiency power adapters for laptops and smartphones to advanced audio-visual equipment, the superior magnetic properties of these alloys enable the design of more compact and power-saving solutions.

Despite its promising growth trajectory, the Fe-based nanocrystalline alloy market is not without its hurdles. One of the primary restraints is the relatively high cost of production compared to traditional soft magnetic materials like silicon steel and amorphous alloys. The complex manufacturing processes, often involving specialized equipment and precise control over alloy composition and annealing conditions, contribute to this premium pricing. This cost factor can limit widespread adoption in price-sensitive applications where marginal performance gains might not justify the increased expenditure. Another significant challenge lies in the nuanced understanding and application of these advanced materials. Optimizing their performance for specific applications requires deep expertise in magnetic material science and engineering. This can create a barrier for smaller manufacturers or companies less experienced with such sophisticated materials, leading to a slower adoption rate. Furthermore, the niche nature of some applications, while driving demand, also limits the overall market volume in the short to medium term. The development of new applications often requires extensive research, prototyping, and testing, which can be time-consuming and resource-intensive. The supply chain for raw materials, while generally stable, can be subject to fluctuations in availability and price of critical elements, potentially impacting production costs and lead times for manufacturers. Finally, competition from alternative advanced magnetic materials, such as certain types of ferrites or other advanced amorphous alloys, can also present a challenge, as these materials may offer specific advantages in certain applications or at a lower cost point.

The Fe-based nanocrystalline alloy market is poised for significant regional and segmental dominance, with Asia-Pacific emerging as the leading force in terms of both production and consumption, driven by its burgeoning manufacturing capabilities and rapid technological adoption across key application sectors. Within this dynamic region, China is expected to spearhead the growth, fueled by its immense manufacturing ecosystem for electronics, electric vehicles, and renewable energy infrastructure. The country's proactive government policies supporting technological innovation and green initiatives further bolster its position. Other countries in the Asia-Pacific region, such as Japan and South Korea, are also significant contributors, known for their advanced research and development in materials science and their established presence in high-tech industries.

Looking at the application segments, New Energy and Consumer Electronics are projected to be the dominant forces shaping the market landscape. The New Energy sector's exponential growth, driven by global decarbonization efforts, necessitates a massive scale-up in renewable energy generation and electric mobility. This translates directly into an increased demand for highly efficient power conversion and management systems, where Fe-based nanocrystalline alloys play a pivotal role. The development of more efficient solar inverters, wind turbine converters, and advanced charging infrastructure for EVs will heavily rely on the superior performance characteristics of these alloys. The ability of Fe-based nanocrystalline alloys to minimize energy loss at high operating frequencies is a critical advantage in these applications, directly impacting the overall efficiency and economic viability of new energy solutions.

In parallel, the Consumer Electronics segment continues its relentless march towards miniaturization, increased functionality, and enhanced energy efficiency. The pervasive use of portable electronic devices, smart home appliances, and sophisticated audio-visual equipment creates a constant demand for smaller, lighter, and more power-efficient power supplies, transformers, and inductors. Fe-based nanocrystalline alloys enable manufacturers to achieve these design goals, leading to more user-friendly and environmentally friendly products. The continuous innovation in consumer electronics, from faster charging technologies to more integrated power management solutions, will ensure a sustained demand for these specialized magnetic materials.

Within the Type segmentation, the Thickness: 18~22μm segment is expected to witness substantial growth, aligning perfectly with the trend towards further miniaturization and higher operating frequencies in both new energy and consumer electronics applications. This specific thickness range offers an optimal balance between magnetic performance, mechanical properties, and manufacturability for a wide array of critical components, making it a sweet spot for innovation and market adoption.

The Fe-based nanocrystalline alloy industry's growth is significantly catalyzed by the global imperative for energy efficiency and the rapid evolution of high-power density electronic devices. The accelerating adoption of electric vehicles worldwide, driven by environmental concerns and government mandates, is a primary catalyst, demanding smaller and more efficient power electronic components. Similarly, the expansion of renewable energy infrastructure, including solar and wind farms, necessitates advanced power conversion systems that minimize energy loss, a forte of these alloys. The continuous miniaturization and increasing power demands of consumer electronics, from smartphones to advanced computing, also serve as a strong growth impetus.

A comprehensive report on Fe-based nanocrystalline alloys would delve into a multi-faceted analysis of the market, covering historical trends from 2019-2024, the current market landscape in 2025, and a detailed forecast for the period 2025-2033. It would meticulously examine the driving forces, such as the burgeoning electric vehicle and renewable energy sectors, and the restraints posed by production costs and technological complexity. The report would provide an in-depth regional analysis, highlighting the dominance of Asia-Pacific, particularly China, and a granular segmentation analysis, emphasizing the significant contributions of the New Energy and Consumer Electronics applications, and the growing importance of Thickness: 18~22μm. Growth catalysts, including government incentives and technological advancements, would be thoroughly explored, alongside a detailed competitive landscape featuring leading players. Furthermore, the report would document significant industry developments, including technological innovations and capacity expansions, offering a complete and actionable overview for stakeholders.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Hitachi Metals, Bomatec, VACUUMSCHMELZE, OJSC MSTATOR, Henan Zhongyue amorphous New Material Co., Ltd, Foshan Zhongyan Magnetic Technology Co., Ltd, Advanced Technology & Materials Co.,Ltd, Foshan Nanhai Xigang Iron Core Manufacturing Co., Ltd, Yeke Technology Co., Ltd, Dayou Scientfic&Technical Co., Ltd, Tera Xtal Technology Corporation, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Fe-based Nanocrystalline Alloy," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Fe-based Nanocrystalline Alloy, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.