1. What is the projected Compound Annual Growth Rate (CAGR) of the Disposable Plastic Bioreactor?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Disposable Plastic Bioreactor

Disposable Plastic BioreactorDisposable Plastic Bioreactor by Type (Mammalian Cells, Bacterial Cells, Yeast Cells, Other), by Application (Pharmaceutical, Research institutes, Others), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

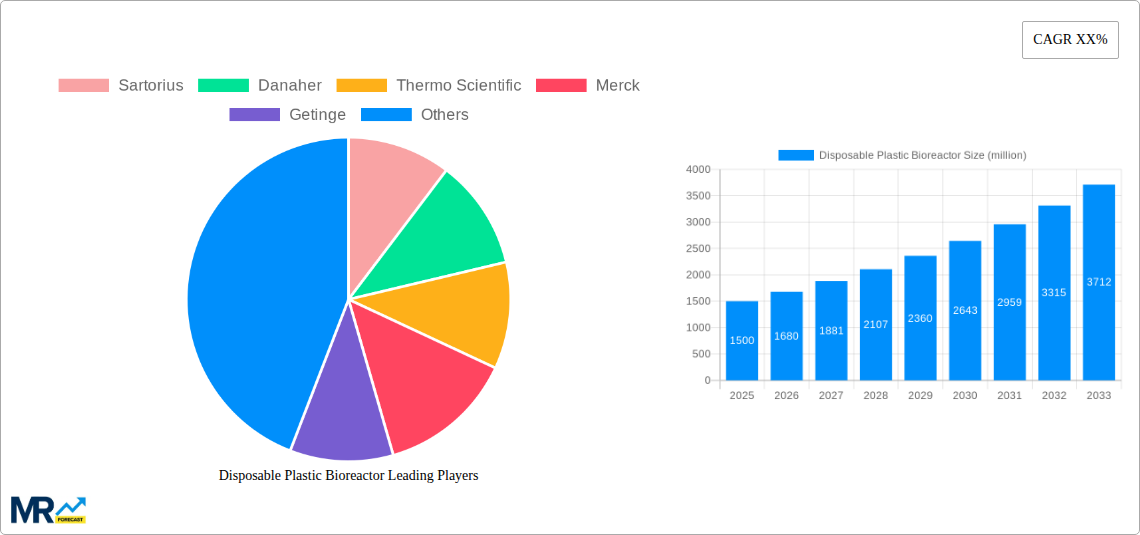

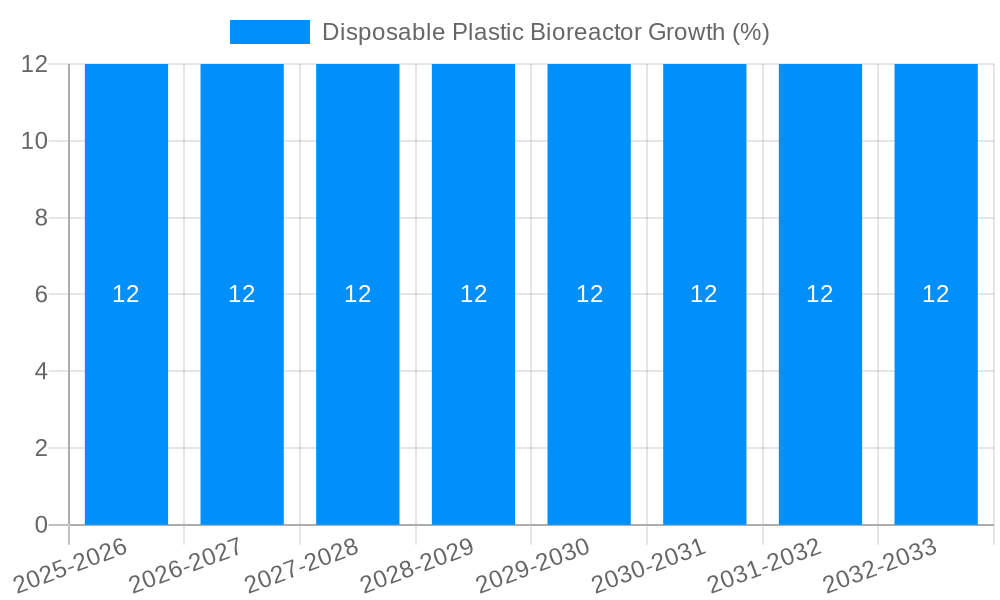

The global Disposable Plastic Bioreactor market is experiencing robust expansion, projected to reach an estimated market size of approximately $1,500 million in 2025. This growth is fueled by a Compound Annual Growth Rate (CAGR) of approximately 12%, indicating a strong and sustained upward trajectory through the forecast period ending in 2033. The increasing demand for biopharmaceuticals, coupled with the inherent advantages of disposable bioreactors such as reduced contamination risk, faster setup times, and lower capital investment, are the primary drivers behind this surge. These benefits are particularly attractive for research institutions and pharmaceutical companies involved in the development of novel biologics, vaccines, and cell-based therapies, where flexibility and sterility are paramount. The adoption of single-use technologies in bioprocessing has become a significant trend, enabling more agile and efficient production workflows.

The market is segmented into key cell types including Mammalian Cells, Bacterial Cells, and Yeast Cells, with mammalian cells likely holding the largest share due to their critical role in producing complex protein therapeutics. Applications are dominated by the pharmaceutical sector, with research institutes also representing a substantial segment. Challenges to market growth, or restraints, may include the higher operational costs associated with frequent disposables for very large-scale or long-term continuous processes, and the need for specialized waste disposal methods. However, the overwhelming advantages of disposables in terms of flexibility, reduced validation efforts, and mitigation of cross-contamination risks are expected to outweigh these restraints, ensuring continued market dominance, especially in the fast-paced research and development phases of biopharmaceutical production. Leading companies like Sartorius, Danaher, Thermo Scientific, and Merck are at the forefront, innovating and expanding their offerings to meet this growing demand across major regions like North America, Europe, and Asia Pacific.

Here is a unique report description on Disposable Plastic Bioreactors, incorporating the provided information and structure:

XXX reports project a robust expansion within the global disposable plastic bioreactor market, anticipated to witness a significant surge from an estimated USD 3,500 million in the base year of 2025 to a projected USD 7,800 million by the end of the forecast period in 2033. This represents a Compound Annual Growth Rate (CAGR) of approximately 10.5% during the forecast period (2025-2033). The historical period (2019-2024) laid the foundation for this growth, with the market demonstrating consistent upward momentum fueled by increasing adoption in various biopharmaceutical processes. The study period (2019-2033) encapsulates a comprehensive analysis of market dynamics, including the foundational historical data, current estimations, and future projections. The market is characterized by a strong emphasis on innovation, with manufacturers continuously introducing novel designs and materials to enhance performance, scalability, and user-friendliness. The increasing demand for single-use technologies across the bioprocessing workflow, from upstream cell culture to downstream purification, is a primary driver. This trend is particularly pronounced in pharmaceutical manufacturing, where the need for flexibility, reduced contamination risk, and faster turnaround times is paramount. The evolution of bioreactor designs, moving beyond simple culture vessels to integrated systems offering advanced monitoring and control capabilities, is further shaping market trends. Companies are investing heavily in research and development to cater to specific cell types and applications, such as mammalian cell culture for monoclonal antibody production and bacterial fermentation for recombinant protein synthesis. The convenience and cost-effectiveness associated with disposable bioreactors, especially for R&D and early-stage clinical trials, are critical factors influencing their widespread adoption. The market's trajectory is also influenced by the growing pipeline of biologics and the subsequent need for efficient and scalable manufacturing solutions. The trend towards decentralization of biomanufacturing and the establishment of flexible manufacturing facilities further propels the demand for disposable bioreactors, allowing for rapid setup and adaptation to varying production needs. Furthermore, the increasing awareness and implementation of stringent regulatory guidelines are indirectly benefiting the disposable bioreactor market, as these technologies inherently reduce the risks associated with cross-contamination and cleaning validation, thereby simplifying regulatory compliance.

The exponential growth of the disposable plastic bioreactor market is propelled by a confluence of powerful driving forces. The burgeoning biopharmaceutical industry, with its ever-increasing pipeline of biologics, vaccines, and gene therapies, necessitates flexible and scalable manufacturing solutions. Disposable bioreactors offer a significant advantage in this regard, allowing for rapid production scale-up and adaptation to fluctuating demand, a critical factor in bringing life-saving treatments to market efficiently. Furthermore, the inherent sterility and reduced risk of cross-contamination associated with single-use technologies are paramount in biopharmaceutical manufacturing, where product integrity and patient safety are non-negotiable. This characteristic simplifies validation processes and significantly reduces the potential for costly batch failures. The accelerating pace of research and development in life sciences, particularly in areas like personalized medicine and regenerative therapies, also fuels demand. Researchers and developers are increasingly turning to disposable bioreactors for their ease of use, cost-effectiveness for small-scale experimentation, and ability to accelerate discovery timelines without the capital investment and extensive validation required for traditional stainless-steel systems. The growing emphasis on modular and flexible manufacturing facilities further bolsters the adoption of disposable bioreactors. These systems enable biomanufacturers to quickly reconfigure production lines, adapt to different product campaigns, and optimize space utilization, thereby enhancing operational agility and reducing overall manufacturing costs. The continuous innovation in material science and bioreactor design, leading to improved cell viability, higher yields, and enhanced process control, also contributes significantly to their market appeal.

Despite the promising growth trajectory, the disposable plastic bioreactor market is not without its challenges and restraints. A primary concern revolves around the environmental impact of single-use plastics. The disposal of these materials, often containing complex biological residues, raises significant waste management issues and environmental sustainability concerns. While recycling and alternative disposal methods are being explored, the sheer volume of waste generated poses a considerable challenge to achieving a truly circular economy within the bioprocessing sector. Another significant restraint is the scalability limitations for very large-scale commercial production. While disposable bioreactors have made significant strides in increasing their capacity, certain ultra-large-scale biopharmaceutical manufacturing processes may still find traditional stainless-steel bioreactors to be more economically viable and technologically mature. The extractables and leachables (E&L) profile of the plastic materials used in bioreactors remains a critical area of scrutiny. Ensuring that no harmful substances leach from the plastic into the cell culture media or the final product is paramount for regulatory approval and product safety, requiring rigorous testing and validation, which can be time-consuming and costly. Furthermore, the initial capital expenditure for adopting disposable bioreactor technology, including the purchase of specialized single-use components and the necessary infrastructure, can still be a barrier for smaller research institutions or companies with limited budgets, especially when compared to the amortized costs of reusable systems over a very long operational lifespan. The dependency on a reliable supply chain for these specialized disposable components is also a factor. Any disruptions in the manufacturing or logistics of these single-use items can lead to significant production delays, impacting the continuity of biopharmaceutical manufacturing.

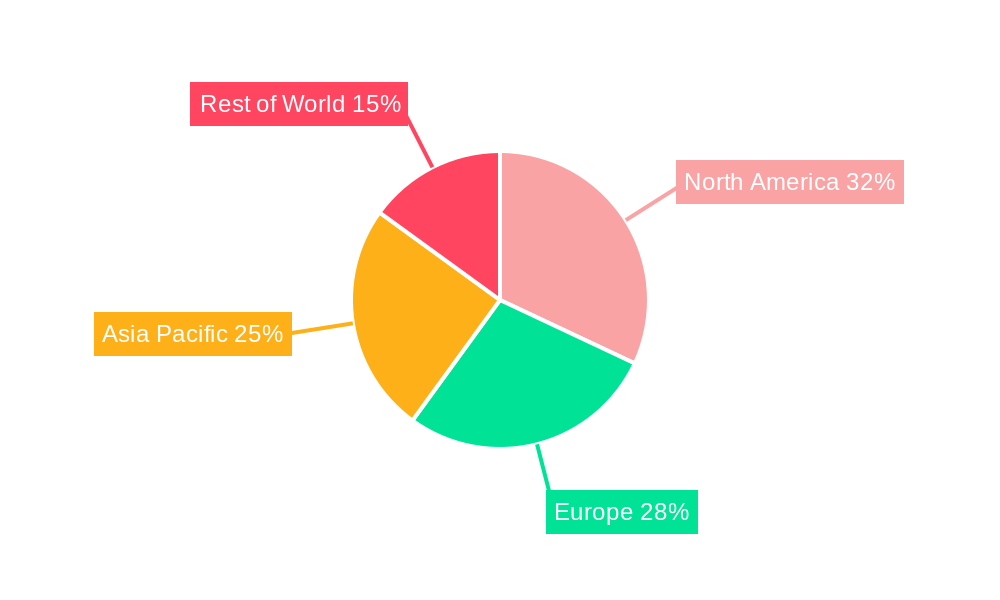

The North America region is poised to maintain its dominance in the global disposable plastic bioreactor market, driven by a robust biopharmaceutical industry, significant investment in R&D, and a strong presence of leading biotechnology and pharmaceutical companies. The United States, in particular, is a powerhouse for drug discovery and development, with a high concentration of research institutes and biomanufacturing facilities actively adopting advanced single-use technologies. This region's commitment to innovation and its proactive approach to adopting new manufacturing paradigms contribute significantly to its market leadership.

In terms of segmentation, the Mammalian Cells segment is expected to be the leading application area for disposable plastic bioreactors, with an estimated market share of over 40% by 2025, projected to reach approximately USD 1,400 million in the base year and grow to an estimated USD 3,120 million by 2033. This dominance is primarily attributed to the crucial role of mammalian cell cultures in the production of monoclonal antibodies, recombinant proteins, and other complex biotherapeutics. The increasing prevalence of chronic diseases and the growing demand for biologics for their treatment are continuously fueling the need for efficient and scalable mammalian cell culture processes. Disposable bioreactors offer distinct advantages in this domain, including reduced risk of viral contamination, simplified cleaning validation, and enhanced flexibility for diverse production scales. The ability to quickly switch between different cell lines and product campaigns, a common requirement in mammalian cell culture-based manufacturing, further underscores the appeal of disposable systems.

The Pharmaceutical application segment is also a major contributor to market growth. The pharmaceutical industry's reliance on high-purity biologics and its continuous pursuit of faster drug development and manufacturing cycles make disposable bioreactors an attractive solution. The ability to minimize downtime between batches, reduce validation efforts, and ensure stringent sterility requirements aligns perfectly with the operational demands of pharmaceutical manufacturing. This segment is estimated to contribute a substantial portion of the market revenue, with projections indicating a growth from an estimated USD 2,000 million in 2025 to USD 4,500 million by 2033. The increasing number of biologic drugs in clinical trials and nearing commercialization directly translates into a higher demand for flexible and scalable biomanufacturing solutions like disposable bioreactors.

Key Regions Dominating the Market:

Key Segments Dominating the Market:

The disposable plastic bioreactor industry is experiencing significant growth catalysts. The escalating demand for biologics, including monoclonal antibodies and vaccines, is a primary driver, necessitating flexible and scalable manufacturing solutions. Advances in cell culture media and upstream processing technologies are enabling higher cell densities and yields, making disposable bioreactors even more efficient. Furthermore, the increasing focus on personalized medicine and rare disease treatments requires agile manufacturing capabilities, which disposable bioreactors readily provide. The growing trend towards decentralization of biomanufacturing and the establishment of modular production facilities further propels their adoption.

This comprehensive report delves into the intricate landscape of the disposable plastic bioreactor market. It offers a granular analysis of market trends, drivers, and restraints, providing insights into the factors shaping the industry's trajectory. The report meticulously examines key regional markets and dominant application segments, highlighting the areas of greatest growth and opportunity. Furthermore, it provides an in-depth overview of leading industry players and their strategic initiatives, alongside a detailed account of significant technological advancements and developments that are revolutionizing bioprocessing. The report aims to equip stakeholders with actionable intelligence to navigate this dynamic and rapidly evolving market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Sartorius, Danaher, Thermo Scientific, Merck, Getinge, Eppendorf, Entegris, Avantor, Corning, Kuhner, CESCO Bioengineering, TECNIC, PBS Biotech, SATAKE MultiMix, G&G Technologies Inc., ABEC, Inc., Bbi-biotech, Reprocell, Cellexus, Distek, Inc., OmniBRx Biotechnologies, New Horizon Biotech, GPC BIO, Meissner Corporation, Cell Culture Company, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Disposable Plastic Bioreactor," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Disposable Plastic Bioreactor, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.