1. What is the projected Compound Annual Growth Rate (CAGR) of the Copper Nickel Sputtering Target?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Copper Nickel Sputtering Target

Copper Nickel Sputtering TargetCopper Nickel Sputtering Target by Type (Purity 99%, Purity 99.5%, Purity 99.9%, Purity 99.95%, Purity 99.99%, Purity 99.999%, World Copper Nickel Sputtering Target Production ), by Application (Semiconductor, Chemical Vapor Deposition, Physical Vapor Deposition, Others, World Copper Nickel Sputtering Target Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

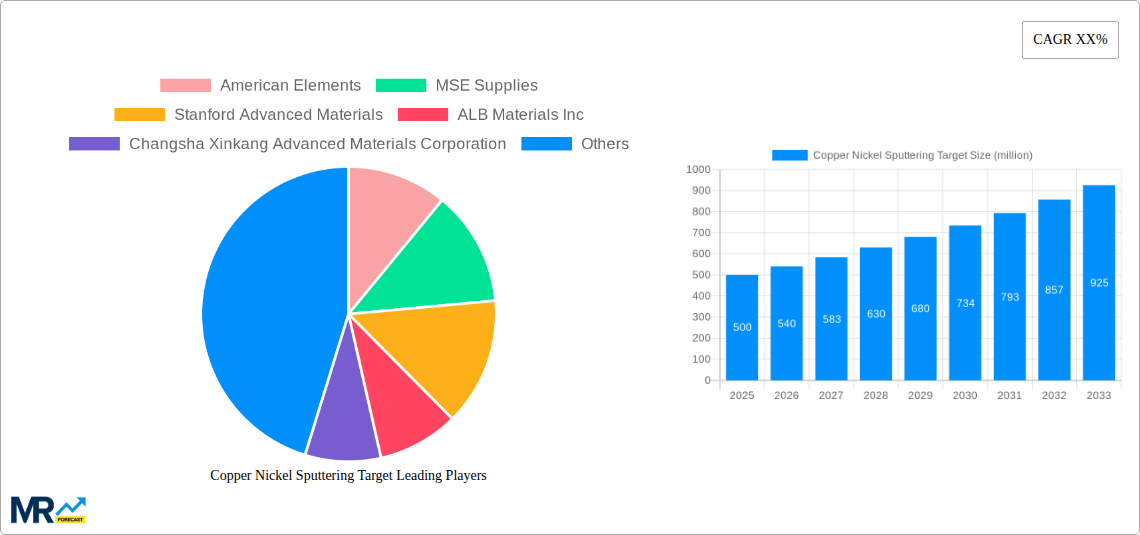

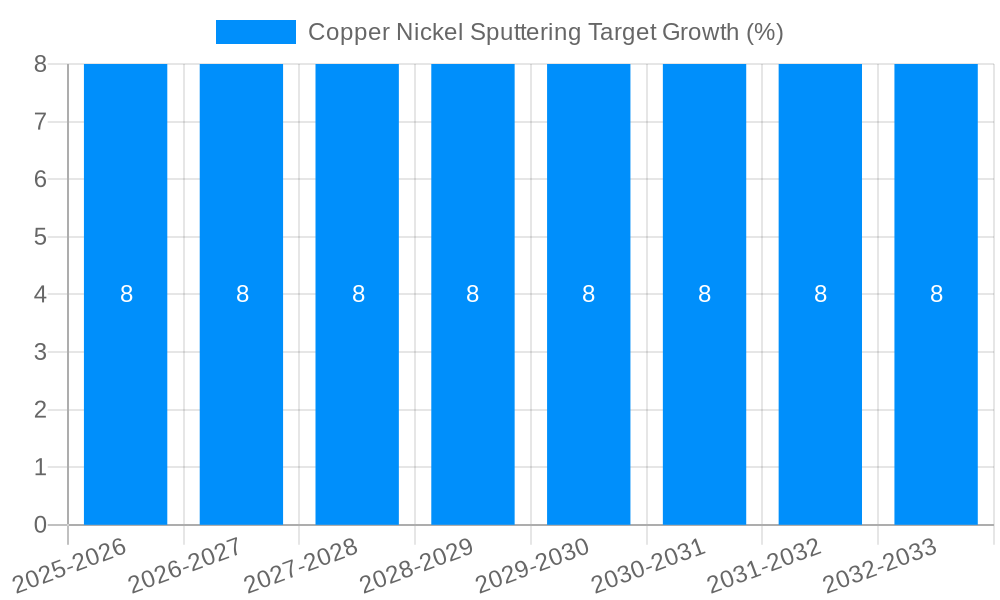

The global Copper Nickel Sputtering Target market is poised for robust growth, projected to reach an estimated market size of $500 million in 2025. This expansion is driven by the increasing demand for advanced materials in critical sectors such as semiconductors and thin-film technologies. The market is expected to witness a Compound Annual Growth Rate (CAGR) of approximately 8% over the forecast period of 2025-2033, indicating a dynamic and evolving landscape. Key growth drivers include the escalating production of advanced electronic devices, the growing adoption of Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) techniques in manufacturing, and the continuous innovation in material science leading to the development of higher purity sputtering targets. The increasing need for high-performance coatings in aerospace, automotive, and medical devices further bolsters market expansion.

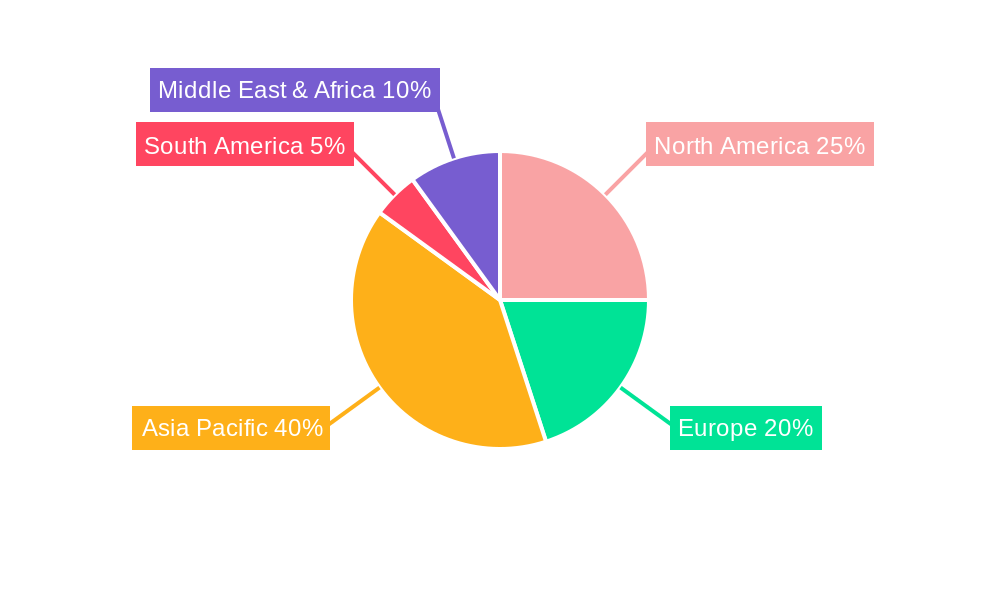

The market is segmented by purity levels, with higher purities such as 99.99% and 99.999% increasingly sought after for specialized applications requiring superior performance and reliability, particularly within the semiconductor industry. The Asia Pacific region, led by China and Japan, is anticipated to dominate the market due to its strong manufacturing base for electronics and significant investments in research and development. North America and Europe also represent substantial markets, driven by their established technological infrastructure and demand for advanced sputtering targets in high-tech industries. Challenges such as fluctuating raw material prices and the need for significant capital investment in advanced manufacturing processes could pose restraints. However, the sustained innovation in sputtering target materials and applications is expected to outweigh these challenges, ensuring a positive trajectory for the Copper Nickel Sputtering Target market.

Here's a unique report description for Copper Nickel Sputtering Targets, incorporating your specified elements:

The global Copper Nickel Sputtering Target market is experiencing a dynamic evolutionary phase, driven by an insatiable demand for advanced materials across high-technology sectors. Our comprehensive analysis, spanning the historical period of 2019-2024 and extending through a robust forecast period of 2025-2033, with a base year set at 2025, reveals a compound annual growth rate (CAGR) poised for significant expansion. In the base year 2025, the estimated production of Copper Nickel Sputtering Targets is projected to reach 50 million units, a figure that underscores the market's current scale. A key trend observed is the increasing preference for higher purity targets, particularly those exceeding 99.99% and even reaching the ultra-high purity of 99.999%. This shift is directly attributable to the stringent requirements of advanced semiconductor fabrication and specialized optical coating applications, where even minute impurities can lead to performance degradation and reduced device yields. The market is also witnessing a notable diversification in target compositions, with manufacturers exploring tailored alloy ratios to meet specific performance metrics for applications like advanced interconnects, protective coatings, and thermal management solutions. The influence of technological advancements in sputtering techniques, such as high-throughput magnetron sputtering and reactive sputtering, is further shaping the demand for optimized sputtering target materials. Geographical trends indicate a concentration of production capabilities and consumption in regions with strong electronics manufacturing ecosystems. The average price per unit, while subject to fluctuations based on purity and volume, is estimated to be around $1.5 million, reflecting the sophisticated manufacturing processes and the critical role these targets play in high-value end products. Furthermore, the report highlights a growing emphasis on sustainability and recyclability within the supply chain, as manufacturers and end-users alike strive for more environmentally responsible material sourcing and utilization. The sheer volume of production, estimated to reach over 80 million units by the end of the forecast period, signifies the expanding importance of Copper Nickel Sputtering Targets in shaping the future of advanced materials. The intricate interplay between technological innovation, evolving application demands, and strategic market positioning by key players is defining the trajectory of this vital market.

The remarkable ascent of the Copper Nickel Sputtering Target market is fundamentally propelled by the relentless innovation and growth witnessed in the semiconductor industry. As the demand for more powerful, efficient, and miniaturized electronic devices continues to surge, so too does the requirement for advanced materials like Copper Nickel sputtering targets. These targets are indispensable for depositing thin films that form critical components such as interconnects, diffusion barriers, and electrodes in integrated circuits. The continuous miniaturization trend, leading to smaller feature sizes on silicon wafers, necessitates sputtering targets with exceptional purity and uniformity to achieve precise film deposition with minimal defects. Beyond semiconductors, the aerospace and defense sectors are contributing significantly, utilizing Copper Nickel alloys for their excellent corrosion resistance and high-temperature performance in critical applications such as radar systems, satellite components, and specialized coatings. The expanding adoption of Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) techniques across diverse industries, including optics, automotive, and renewable energy, further amplifies the demand for high-quality sputtering targets. The increasing application of these targets in creating advanced optical coatings for lenses, mirrors, and displays, where precise refractive index control and durability are paramount, is another key growth driver. The estimated production volume, projected to exceed 75 million units within the forecast period, is a direct reflection of these multifaceted demands. The average price point of approximately $1.7 million per unit for high-purity targets highlights the value embedded in these advanced materials, further incentivizing production and innovation.

Despite the robust growth trajectory, the Copper Nickel Sputtering Target market is not without its inherent challenges and restraints. One significant hurdle is the volatility in raw material prices, particularly for copper and nickel. Fluctuations in global commodity markets can directly impact the production costs of sputtering targets, leading to price instability for end-users and affecting profit margins for manufacturers. The intricate and highly specialized nature of sputtering target manufacturing demands significant capital investment in advanced production equipment and stringent quality control processes. This can act as a barrier to entry for new players and limit the expansion capabilities of existing ones. Furthermore, the increasing stringency of environmental regulations related to the mining, processing, and disposal of metals like copper and nickel can impose additional compliance costs and operational complexities on manufacturers. The development and adoption of ultra-high purity targets, while a growth catalyst, also present a significant technical challenge. Achieving and consistently maintaining purities of 99.999% requires sophisticated purification techniques, advanced analytical methods for quality assurance, and meticulous handling to prevent contamination throughout the production and supply chain. Any lapse in quality control can lead to batch rejections, substantial financial losses, and reputational damage. The complex supply chain logistics for high-value, often sensitive materials like sputtering targets can also be a restraint, especially when dealing with global distribution and the need for specialized packaging and transportation to maintain material integrity. The estimated market size of 55 million units in the base year 2025, while substantial, is also influenced by the lead times and production capacity constraints inherent in manufacturing these precision materials. The average cost, around $1.6 million per unit, reflects these production complexities and the high investment required to overcome these challenges.

The global Copper Nickel Sputtering Target market exhibits a clear geographical and segment dominance, driven by established technological ecosystems and concentrated end-user industries.

Dominant Regions/Countries:

Dominant Segments:

The interplay between these dominant regions and segments creates a concentrated market, with innovations and growth in one area often cascading to influence others. The estimated average price for these premium purity targets can range from $1.8 million to $2.5 million per unit, reflecting the sophisticated manufacturing processes and stringent quality control required.

The Copper Nickel Sputtering Target industry is propelled by several potent growth catalysts. The relentless miniaturization and increasing complexity of semiconductor devices are paramount, demanding ever-higher purity and uniformity from sputtering targets to ensure reliable performance. The expansion of 5G infrastructure and the proliferation of AI-driven applications further accelerate semiconductor innovation, creating sustained demand. Additionally, the burgeoning demand for advanced optical coatings in augmented reality (AR) and virtual reality (VR) devices, as well as in high-performance cameras and displays, provides a significant impetus. Growth in the aerospace and defense sectors, driven by the need for robust and reliable components capable of withstanding extreme conditions, also contributes to market expansion. The increasing adoption of PVD and CVD technologies across a broader spectrum of industrial applications, from automotive components to renewable energy solutions, further broadens the market base for these essential sputtering materials.

This comprehensive report provides an in-depth analysis of the global Copper Nickel Sputtering Target market, offering detailed insights into its current landscape and future trajectory. The study encompasses historical data from 2019-2024 and projects market dynamics through 2033, with a keen focus on the base year 2025. It meticulously examines market trends, key driving forces such as advancements in semiconductor technology and aerospace applications, and the challenges faced by the industry, including raw material price volatility and stringent environmental regulations. The report identifies dominant regions and segments, with a particular emphasis on ultra-high purity targets (99.99% and 99.999%) and their critical role in the semiconductor sector, where production is estimated to reach 45 million units in the base year. Leading players are profiled, and significant market developments, including technological advancements and capacity expansions, are highlighted. The report's detailed segmentation by purity levels (from 99% to 99.999%), application areas (Semiconductor, Chemical Vapor Deposition, Physical Vapor Deposition, Others), and production volumes (estimated at 50 million units in 2025) provides a granular understanding of the market's structure and potential. The estimated average price of $1.5 million per unit for standard purity targets underscores the value proposition of these critical materials. This report is an essential resource for stakeholders seeking to understand the intricate dynamics and future prospects of the Copper Nickel Sputtering Target market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include American Elements, MSE Supplies, Stanford Advanced Materials, ALB Materials Inc, Changsha Xinkang Advanced Materials Corporation, Heeger Materials, Edgetech Industries, Stanford Materials Corporation.

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Copper Nickel Sputtering Target," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Copper Nickel Sputtering Target, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.