1. What is the projected Compound Annual Growth Rate (CAGR) of the CNC Sheet Metal Press Machines?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

CNC Sheet Metal Press Machines

CNC Sheet Metal Press MachinesCNC Sheet Metal Press Machines by Type (CNC Punching Press, CNC Bending Machines, CNC Shearing Machines, World CNC Sheet Metal Press Machines Production ), by Application (Machinery, Electrical Appliances, Instruments, Others, World CNC Sheet Metal Press Machines Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

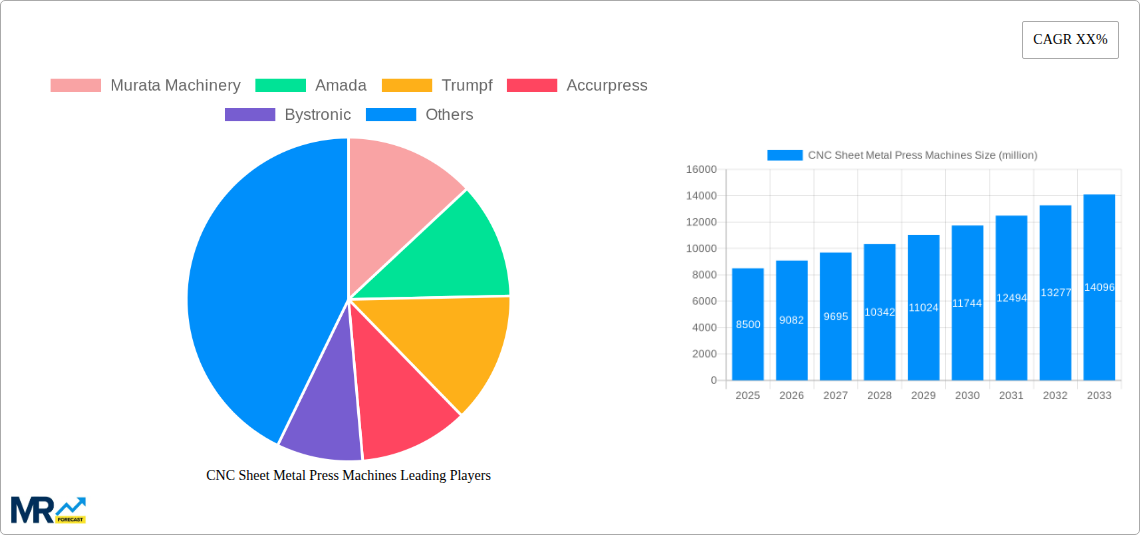

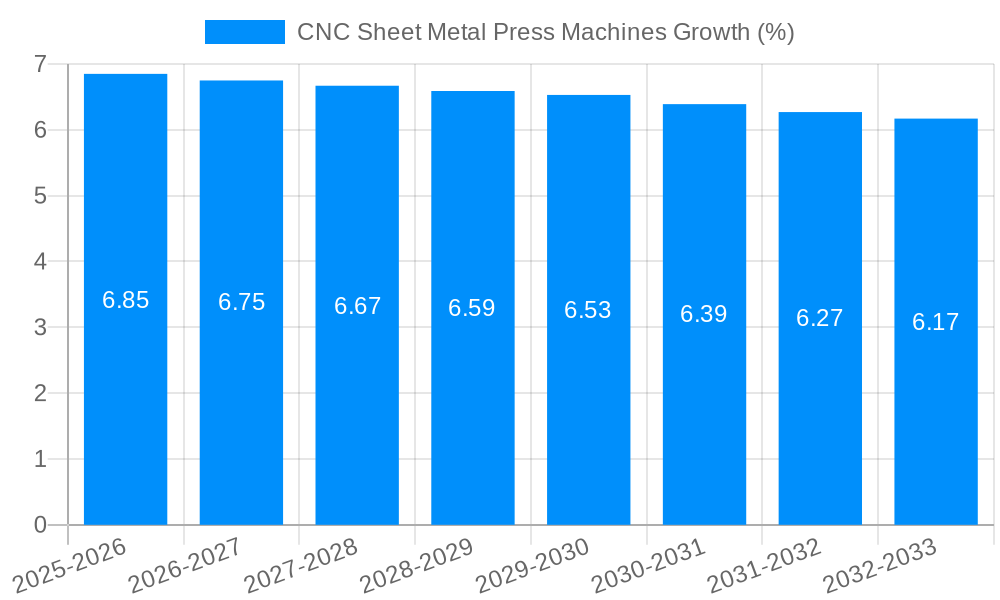

The global CNC Sheet Metal Press Machines market is experiencing robust growth, projected to reach approximately $8,500 million by 2025, with an estimated Compound Annual Growth Rate (CAGR) of 6.5% during the forecast period of 2025-2033. This expansion is primarily fueled by the increasing demand for precision manufacturing across diverse industries such as machinery, electrical appliances, and instruments. Advancements in automation and the rising adoption of Industry 4.0 principles are driving the demand for high-efficiency and accurate CNC punching presses, CNC bending machines, and CNC shearing machines. The market's trajectory is further bolstered by government initiatives supporting manufacturing modernization and the growing need for sophisticated sheet metal fabrication solutions to meet complex design requirements.

Despite strong growth, certain factors could moderate the market's pace. High initial investment costs for advanced CNC machinery and the availability of skilled labor to operate and maintain these complex systems present significant restraints. Furthermore, the increasing use of alternative materials and manufacturing techniques in certain applications could pose challenges. However, the inherent benefits of CNC sheet metal press machines, including enhanced productivity, superior accuracy, and reduced waste, are expected to outweigh these limitations. Key regions like Asia Pacific, driven by China and India's burgeoning manufacturing sectors, are anticipated to lead market expansion, followed by North America and Europe. Leading companies like Murata Machinery, Amada, and Trumpf are actively investing in research and development to introduce innovative products and expand their global presence.

Here's a comprehensive report description on CNC Sheet Metal Press Machines, incorporating your specified elements:

This in-depth report offers a granular analysis of the global CNC Sheet Metal Press Machines market, spanning a comprehensive Study Period of 2019-2033. With the Base Year set at 2025, the report provides an Estimated Year of 2025 and a detailed Forecast Period from 2025-2033, building upon the Historical Period of 2019-2024. The market is poised for significant evolution, with projections indicating a robust expansion, potentially reaching hundreds of millions of units in production and market value by the end of the forecast period. We delve into the intricate dynamics, examining key trends, driving forces, persistent challenges, and the strategic maneuvers of leading players. The report further dissects the market by critical segments and regions, identifying areas of dominance and emerging opportunities. Our analysis aims to equip stakeholders with actionable intelligence to navigate this dynamic industry, from manufacturers and suppliers to investors and end-users.

The global CNC Sheet Metal Press Machines market is experiencing a transformative period characterized by several overarching trends that are reshaping manufacturing landscapes worldwide. A significant shift is the escalating demand for automation and intelligent manufacturing solutions, driven by the relentless pursuit of enhanced productivity, reduced labor costs, and improved precision across various industries. This is directly fueling the adoption of advanced CNC technologies, which offer unparalleled control, repeatability, and the ability to handle complex geometries with ease. The integration of Industry 4.0 principles, including the Internet of Things (IoT), artificial intelligence (AI), and big data analytics, is becoming increasingly prevalent. These technologies enable real-time monitoring, predictive maintenance, and optimized production workflows, leading to substantial efficiency gains. For instance, smart CNC machines can self-diagnose issues, communicate with other factory equipment, and adapt production parameters on the fly, minimizing downtime and maximizing output. The report projects that by 2025, the market penetration of these intelligent features will reach unprecedented levels, contributing to an estimated growth trajectory that could see the production volume of CNC Sheet Metal Press Machines ascend into the tens of millions of units annually. Furthermore, there's a discernible trend towards greater customization and flexibility in manufacturing. As end-users require increasingly specialized components and shorter production runs, CNC machines are evolving to offer quick tool changes, adaptable software interfaces, and the capacity to handle a wider range of materials and thicknesses. This agility is crucial for industries such as automotive, aerospace, and consumer electronics, where product lifecycles are shortening and innovation is paramount. The environmental consciousness within the manufacturing sector is also influencing trends, with a growing emphasis on energy-efficient designs, waste reduction, and the use of sustainable materials. Manufacturers are investing in research and development to create machines that consume less power and produce fewer emissions, aligning with global sustainability goals and regulatory pressures. The increasing complexity of designs and the need for high-quality finishes are pushing the boundaries of precision engineering, with manufacturers of CNC Sheet Metal Press Machines continuously innovating to deliver machines with tighter tolerances and superior surface integrity.

The robust growth of the CNC Sheet Metal Press Machines market is being propelled by a confluence of powerful economic, technological, and industrial factors. A primary driver is the sustained expansion of key end-user industries, including machinery manufacturing, electrical appliances, and instrumentation. As these sectors experience increased demand for their products, the need for efficient and precise metal fabrication solutions escalates, directly benefiting the CNC sheet metal press market. The global push towards industrial automation and smart manufacturing remains a dominant force. Companies are increasingly investing in advanced machinery to optimize production processes, enhance quality, and reduce operational costs, making CNC machines a critical component of modern factories. The advent of Industry 4.0 technologies, such as AI, IoT, and cloud computing, is further accelerating this adoption by enabling greater connectivity, data-driven decision-making, and predictive maintenance capabilities, which significantly improve machine uptime and overall equipment effectiveness. Moreover, the continuous innovation in CNC technology itself, leading to machines that offer higher speeds, greater accuracy, and more sophisticated functionalities, is a significant propellant. These advancements make CNC machines more accessible and attractive to a wider range of manufacturers, including small and medium-sized enterprises (SMEs). The increasing complexity of product designs in sectors like automotive and aerospace, demanding intricate metal components, necessitates the precision and versatility offered by CNC bending and punching machines, thus driving their demand. Furthermore, favorable government policies and incentives aimed at promoting manufacturing and technological upgrades in various countries are providing a conducive environment for market growth. The increasing global trade and the resultant demand for manufactured goods across different continents also contribute to the upward trajectory of the CNC Sheet Metal Press Machines market, with projections indicating a potential surge in production volumes well into the tens of millions of units by 2025 and beyond.

Despite the robust growth, the CNC Sheet Metal Press Machines market is not without its hurdles. A significant challenge is the high initial investment required for acquiring advanced CNC machines. The capital expenditure can be substantial, posing a barrier for smaller enterprises or those in developing economies, thus potentially limiting the widespread adoption of the latest technologies. This financial constraint can slow down the transition from traditional manufacturing methods to automated CNC processes, impacting overall market penetration. Skilled workforce shortage represents another critical restraint. Operating and maintaining sophisticated CNC machines requires specialized knowledge and technical expertise. The lack of a sufficiently trained workforce can lead to inefficient machine utilization, increased downtime, and difficulties in implementing advanced functionalities, thereby hindering the full potential of these technologies. The rapid pace of technological advancement also presents a challenge. While innovation drives progress, it can also lead to obsolescence of existing machinery, forcing manufacturers to constantly upgrade their equipment to remain competitive. This necessitates continuous investment and can create a cycle of depreciation and reinvestment that some companies find difficult to manage. Furthermore, the complexity of integration with existing manufacturing systems and the need for robust cybersecurity measures to protect sensitive production data are emerging concerns. Ensuring seamless data flow and preventing cyber threats in a connected factory environment requires significant investment in IT infrastructure and expertise. The volatility in raw material prices, particularly steel and aluminum, can impact the cost of manufacturing CNC machines, potentially affecting profit margins and pricing strategies. Fluctuations in these costs can create unpredictability in the market. Additionally, stringent environmental regulations related to manufacturing processes and emissions, while ultimately beneficial for sustainability, can necessitate costly upgrades and modifications to existing machinery and production lines, adding another layer of complexity and cost for manufacturers in the sector.

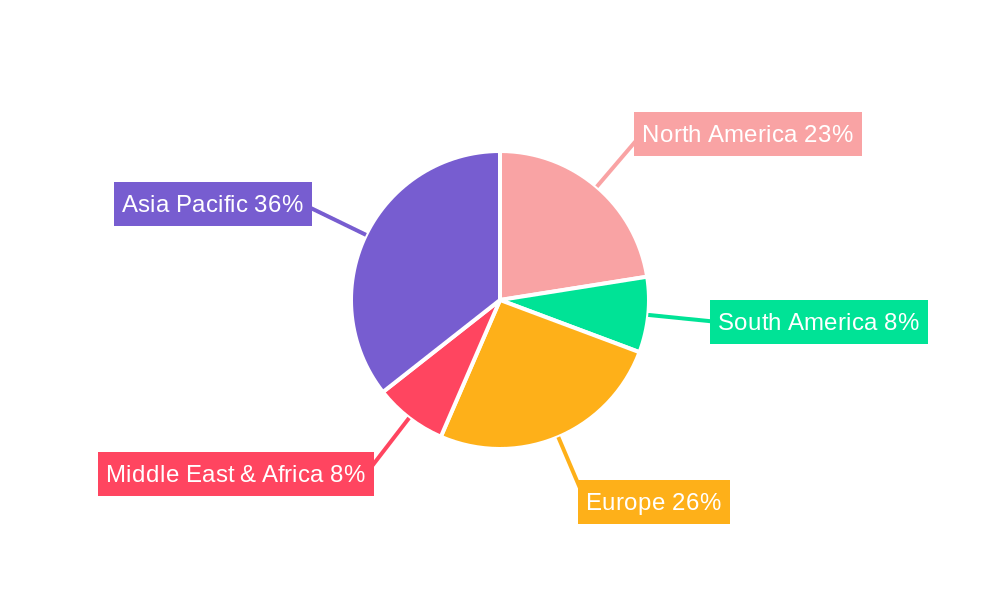

The global CNC Sheet Metal Press Machines market is characterized by distinct regional strengths and segment leadership, with significant dominance expected to be exerted by specific geographical areas and product categories.

Asia-Pacific: This region is poised to maintain its position as the largest and fastest-growing market for CNC Sheet Metal Press Machines.

North America: This region, particularly the United States, remains a crucial market due to its advanced manufacturing capabilities and strong presence in industries like aerospace, automotive, and medical devices. The focus on reshoring manufacturing and investing in cutting-edge technology to maintain global competitiveness will continue to fuel demand.

Europe: Countries like Germany, Italy, and France are at the forefront of industrial automation and precision engineering. The robust automotive, industrial machinery, and aerospace sectors in Europe are significant drivers of the CNC Sheet Metal Press Machines market. The region's commitment to Industry 4.0 principles ensures continued investment in advanced manufacturing technologies.

Type: CNC Bending Machines: This segment is expected to lead the market in terms of both production volume and value. The increasing demand for complex, precisely formed metal parts in industries like automotive (for chassis, body panels), aerospace (for aircraft components), and construction (for structural elements) directly fuels the need for advanced CNC bending solutions. The ability of these machines to perform intricate bends with high repeatability and accuracy makes them indispensable for modern manufacturing. The market for CNC Bending Machines is anticipated to see a significant increase in production, potentially reaching millions of units annually by 2025 and growing exponentially through the forecast period.

Application: Machinery: The "Machinery" application segment is a perpetual powerhouse for CNC Sheet Metal Press Machines. This encompasses the manufacturing of industrial machinery, agricultural equipment, construction machinery, and machine tools themselves. The need for precisely fabricated metal components for these diverse and essential products ensures a constant and substantial demand. As global infrastructure projects and industrial upgrades continue, the demand for machinery, and consequently the sheet metal parts required for their construction, will remain a primary driver for CNC sheet metal press machine sales.

Application: Electrical Appliances: With the ever-increasing consumer demand for a wide array of electrical and electronic devices, from household appliances to sophisticated electronic components, the "Electrical Appliances" segment is a significant contributor to the CNC Sheet Metal Press Machines market. The precise and high-volume production of casings, enclosures, internal structures, and intricate metal parts for these devices relies heavily on the efficiency and accuracy of CNC punching and bending machines. This segment is expected to see sustained growth, contributing to the overall market expansion.

The CNC Sheet Metal Press Machines industry is poised for substantial growth, propelled by several key catalysts. The accelerating trend towards industrial automation and smart manufacturing across all sectors is a primary driver, pushing businesses to invest in technologies that enhance efficiency and reduce labor costs. Furthermore, the ongoing evolution of Industry 4.0, with its integration of AI, IoT, and data analytics, enables more intelligent and connected manufacturing processes, making CNC machines indispensable. The increasing demand for customized and complex metal parts in burgeoning industries such as electric vehicles, renewable energy, and advanced electronics necessitates the precision and flexibility offered by modern CNC machines. Government initiatives promoting domestic manufacturing and technological upgrades in various countries also provide a significant impetus.

The global CNC Sheet Metal Press Machines market is characterized by the presence of a few dominant global players and several regional specialists. The competitive landscape is shaped by innovation, technological advancements, and strategic partnerships.

The CNC Sheet Metal Press Machines sector has witnessed numerous significant developments over the years, reflecting a constant drive for innovation and market adaptation.

This comprehensive report delves into the intricate workings of the global CNC Sheet Metal Press Machines market, offering a detailed analysis spanning from 2019 to 2033, with 2025 serving as the Base Year and Estimated Year. It meticulously examines market trends, identifying key shifts towards intelligent automation and Industry 4.0 integration. The report further elucidates the primary driving forces, such as the expansion of end-user industries and technological advancements, while also addressing critical challenges like high initial investment and skilled workforce shortages. A significant portion of the analysis is dedicated to identifying dominant regions and segments, such as the Asia-Pacific region and the CNC Bending Machines segment, projecting their substantial contribution to the market's growth, potentially involving millions of units in production. The report concludes by highlighting growth catalysts and a comprehensive list of leading players, providing stakeholders with a holistic understanding and strategic insights into this dynamic market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Murata Machinery, Amada, Trumpf, Accurpress, Bystronic, Durma, Salvagnini, LVD, Cincinnati, Haco, Prima Power, KNUTH Machine, Selmach Machinery, ADH, Jiangsu Yangli Group, ACCURL, Ningbo Outai Intelligent Machinery, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "CNC Sheet Metal Press Machines," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the CNC Sheet Metal Press Machines, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.