1. What is the projected Compound Annual Growth Rate (CAGR) of the Chemical Temperature Controlled Packaging?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Chemical Temperature Controlled Packaging

Chemical Temperature Controlled PackagingChemical Temperature Controlled Packaging by Type (Disposable, Reusable, World Chemical Temperature Controlled Packaging Production ), by Application (Chemical Plant, Research Institutions, Other), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

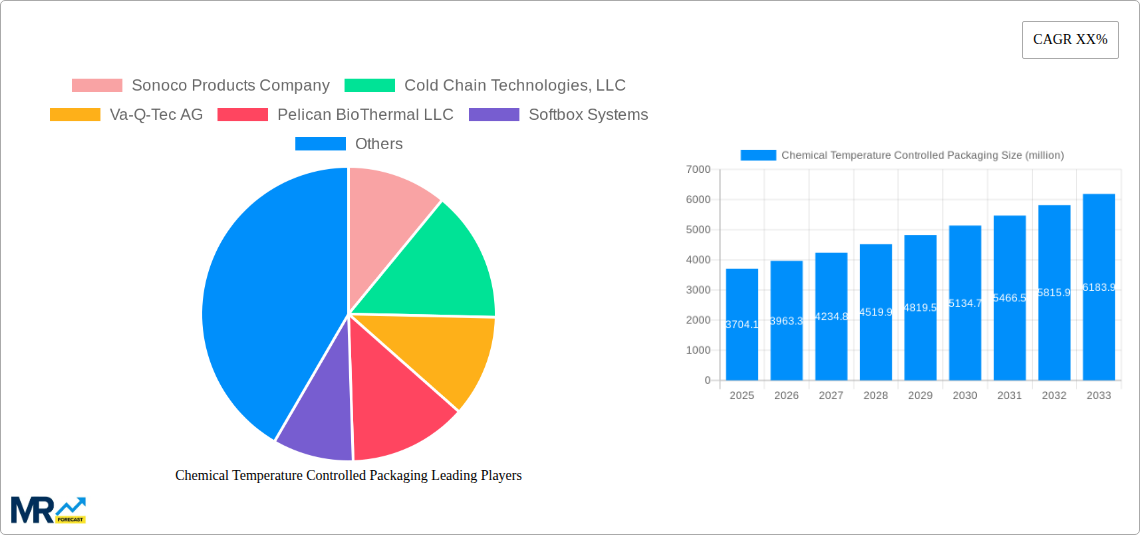

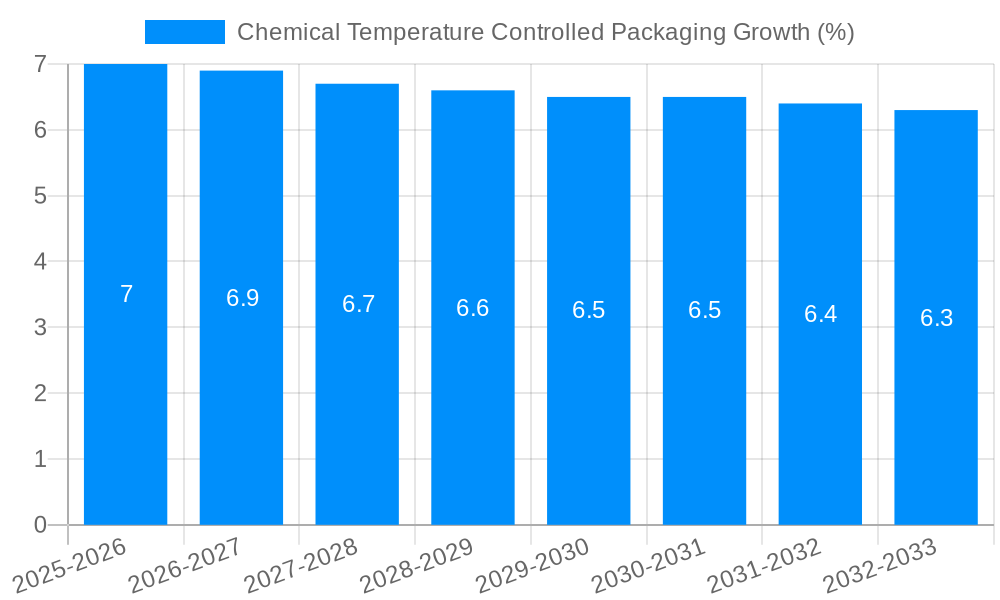

The global Chemical Temperature Controlled Packaging market is poised for significant expansion, currently valued at approximately $3704.1 million. This robust market is anticipated to experience a substantial Compound Annual Growth Rate (CAGR), estimated to be in the range of 6-8%, driven by the increasing demand for safe and compliant transportation of sensitive chemical compounds. Key growth drivers include the escalating production of specialized chemicals requiring stringent temperature control during transit, a rise in pharmaceutical and biotechnology research necessitating the reliable transport of temperature-sensitive biological materials, and the growing global trade of hazardous chemicals that demand secure and regulated packaging solutions. The market's expansion is further bolstered by advancements in insulation technologies, the development of intelligent packaging with real-time temperature monitoring capabilities, and the increasing stringency of international regulations governing the transportation of chemicals, particularly those classified as dangerous goods.

The competitive landscape features a mix of established players and emerging innovators, with companies like Sonoco Products Company, Cold Chain Technologies, LLC, and Va-Q-Tec AG leading the charge. Trends like the adoption of sustainable and eco-friendly packaging materials, the integration of IoT for enhanced cold chain visibility, and the development of customized packaging solutions for specific chemical types are shaping market dynamics. However, certain restraints such as the high initial investment costs for advanced temperature-controlled packaging systems, fluctuations in raw material prices, and the complexity of global logistics and customs regulations can pose challenges. Despite these hurdles, the persistent need for reliable temperature management across the chemical supply chain, from manufacturing facilities to research institutions, underscores a strong and sustained growth trajectory for the Chemical Temperature Controlled Packaging market in the coming years.

The global Chemical Temperature Controlled Packaging (TCP) market is poised for substantial growth, driven by an increasing demand for the safe and efficient transport of sensitive chemical compounds. This report provides an in-depth analysis of the market, encompassing historical trends, future projections, and key influencing factors.

The chemical temperature-controlled packaging market is experiencing a significant surge in demand, driven by a confluence of factors including the burgeoning pharmaceutical and biopharmaceutical industries, the increasing complexity and sensitivity of chemical compounds, and the ever-stringent regulatory landscape governing the transportation of hazardous and temperature-sensitive materials. The World Chemical Temperature Controlled Packaging Production is estimated to reach a colossal USD 4,500 million by the Base Year of 2025, with projections indicating a continued upward trajectory, potentially reaching USD 8,000 million by the end of the Forecast Period in 2033. This expansion is largely fueled by advancements in insulation materials and phase-change materials (PCMs), which are enabling the creation of more sophisticated and reliable temperature-controlled solutions. The market is witnessing a clear bifurcation in its structure, with both disposable and reusable packaging segments experiencing robust growth. The disposable segment, while offering convenience and cost-effectiveness for single-use applications, is increasingly being challenged by the growing emphasis on sustainability and circular economy principles. This has led to a significant rise in the adoption of reusable TCP solutions, which, despite a higher initial investment, offer considerable long-term cost savings and a reduced environmental footprint. The reusable segment is expected to outpace the disposable segment in terms of growth rate during the forecast period. Furthermore, the application landscape is diversifying, with significant contributions from chemical plants for the transport of raw materials and finished products, as well as research institutions requiring precise temperature control for delicate reagents and biological samples. The emergence of "other" applications, encompassing niche sectors and emerging chemical industries, is also contributing to the overall market expansion. The study period of 2019-2033, with a base year of 2025, allows for a thorough examination of the historical growth patterns observed during the 2019-2024 historical period and forecasts a dynamic market evolution in the coming decade.

Several powerful forces are acting as catalysts for the growth of the chemical temperature-controlled packaging market. Foremost among these is the relentless expansion of the global pharmaceutical and biopharmaceutical sectors. The development of novel drugs, vaccines, and biologics, many of which are highly sensitive to temperature fluctuations, necessitates robust and reliable cold chain logistics. The increasing complexity and value of these chemical products translate directly into a higher demand for sophisticated temperature-controlled packaging solutions that can maintain precise temperature ranges throughout the supply chain. Furthermore, the globalization of supply chains for chemical products means that these sensitive materials are being transported across greater distances and through more diverse climatic conditions, amplifying the need for advanced insulation and temperature regulation technologies. The ever-evolving regulatory environment, with stricter guidelines from bodies such as the FDA, EMA, and others, also plays a pivotal role. Compliance with these regulations, which often mandate specific temperature excursions and validation protocols, compels manufacturers and distributors to invest in high-performance TCP solutions. The growing awareness and emphasis on product integrity and patient safety are further driving the adoption of best-in-class temperature-controlled packaging to prevent degradation and ensure efficacy.

Despite the strong growth trajectory, the chemical temperature-controlled packaging market is not without its hurdles. One of the primary challenges is the high cost associated with advanced temperature-controlled packaging solutions, particularly for reusable systems. The initial investment in specialized containers, active cooling units, and sophisticated monitoring devices can be substantial, posing a barrier for smaller enterprises or those operating on tighter margins. Furthermore, the complexity of managing reusable packaging logistics, including the return, cleaning, and maintenance of containers, adds operational costs and can lead to inefficiencies if not managed effectively. The disposal of certain types of insulation materials, particularly those containing refrigerants with environmental implications, presents another significant challenge. Growing environmental concerns and stricter regulations on waste management are pushing the industry towards more sustainable and recyclable materials, but the transition requires significant research, development, and investment. The lack of standardized protocols and testing methods across different regions and industries can also create confusion and hinder seamless global adoption. Ensuring the integrity of the cold chain across diverse transportation modes (air, sea, road) and varying climatic conditions remains a constant operational challenge. Finally, supply chain disruptions, whether due to geopolitical events, natural disasters, or pandemics, can significantly impact the availability of raw materials and the timely delivery of temperature-controlled packaging, affecting market stability.

The global Chemical Temperature Controlled Packaging market is characterized by distinct regional dynamics and segment dominance.

North America is projected to be a dominant region, driven by its highly developed pharmaceutical and biotechnology sectors, which are major consumers of sophisticated cold chain solutions. The presence of leading research institutions and a strong regulatory framework further propels demand for compliant and reliable temperature-controlled packaging. The United States, in particular, accounts for a substantial share of the market due to its extensive pharmaceutical manufacturing capabilities and a robust distribution network.

Europe is another key region with significant market share, owing to its established pharmaceutical industry, a growing biopharmaceutical sector, and stringent regulations governing the transport of medicinal products and chemicals. Countries like Germany, the United Kingdom, and Switzerland are major contributors to this regional dominance, supported by advanced logistics infrastructure and a strong emphasis on product quality and patient safety.

Asia Pacific is anticipated to witness the fastest growth rate. This surge is fueled by the expanding pharmaceutical and chemical manufacturing hubs in countries such as China and India, coupled with increasing investments in healthcare infrastructure and a growing awareness of the importance of maintaining the cold chain for sensitive products. The increasing disposable incomes and the demand for high-quality pharmaceuticals in emerging economies are also significant drivers.

Considering the Type segment, the Reusable Chemical Temperature Controlled Packaging segment is poised to dominate the market in the long run. While the Disposable segment offers convenience for specific applications and smaller volumes, the increasing focus on sustainability, environmental regulations, and long-term cost-effectiveness is driving the adoption of reusable solutions.

The chemical temperature-controlled packaging industry is experiencing a potent surge fueled by several key growth catalysts. The escalating demand for biopharmaceuticals and advanced therapies, which are highly temperature-sensitive, directly translates into a greater need for reliable cold chain solutions. Furthermore, the increasing stringency of global regulations regarding the transport of hazardous and temperature-sensitive chemicals necessitates the adoption of high-performance packaging. Advancements in insulation technologies, including the development of more efficient phase-change materials (PCMs) and vacuum insulated panels (VIPs), are enabling longer hold times and more precise temperature control, making TCP solutions more attractive. The growing emphasis on sustainability and the circular economy is also driving innovation in reusable packaging, reducing waste and offering long-term cost benefits.

This comprehensive report offers an exhaustive examination of the global chemical temperature-controlled packaging market, delving into the intricate details of its growth trajectory and future potential. It meticulously analyzes the market dynamics, including historical performance during the 2019-2024 period and provides precise forecasts for the 2025-2033 forecast period, with the base year set at 2025. The report scrutinizes key trends such as the growing preference for reusable packaging solutions, driven by sustainability initiatives and cost-effectiveness, and the increasing demand from diverse applications including chemical plants and research institutions. It further explores the critical factors propelling market expansion, such as the burgeoning pharmaceutical industry and stringent regulatory requirements, while also addressing the challenges and restraints that may impede growth, including high initial costs and complex logistics. The detailed regional analysis highlights dominant markets and high-growth regions, providing strategic insights for stakeholders. The report also identifies the leading players and significant developments within the sector, offering a complete and actionable understanding of this dynamic and vital market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Sonoco Products Company, Cold Chain Technologies, LLC, Va-Q-Tec AG, Pelican BioThermal LLC, Softbox Systems, Sofrigam SA, DGP Intelsius GMBH, United Parcel Service, Inc., Envirotainer AB, FedEx Corporation, ACH Foam Technologies,LLC, Tempack Packaging Solutions, S.L., Exeltainer, Cryopak A TCP Company, Sorbafreeze Ltd, .

The market segments include Type, Application.

The market size is estimated to be USD 3704.1 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Chemical Temperature Controlled Packaging," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Chemical Temperature Controlled Packaging, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.