1. What is the projected Compound Annual Growth Rate (CAGR) of the Carbon Fiber Air Tank?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Carbon Fiber Air Tank

Carbon Fiber Air TankCarbon Fiber Air Tank by Type (Pan Carbon Fiber, Pitch Carbon Fiber, Ravon Carbon Fiber, World Carbon Fiber Air Tank Production ), by Application (Aerospace, Automotive, Firefighting, Private Use, Others, World Carbon Fiber Air Tank Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

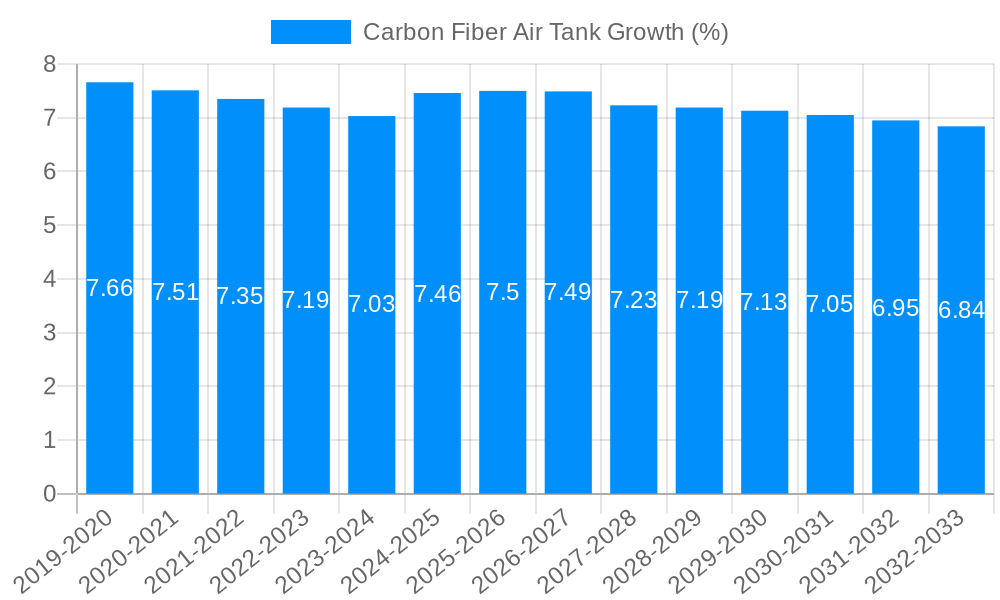

The global carbon fiber air tank market is poised for robust expansion, projected to reach an estimated USD 3,500 million by 2025, driven by a compound annual growth rate (CAGR) of approximately 8.5% from 2019 to 2033. This significant growth is primarily fueled by the increasing demand for lightweight, high-strength air tanks across a diverse range of applications. The aerospace sector is a major contributor, utilizing these advanced materials for enhanced fuel efficiency and payload capacity. Similarly, the automotive industry is witnessing a surge in adoption for compressed natural gas (CNG) and hydrogen fuel cell vehicles, where the superior strength-to-weight ratio of carbon fiber is crucial for safety and performance. Furthermore, the growing need for reliable and portable breathing apparatus in firefighting and industrial safety applications, along with the expanding recreational markets like paintball and SCUBA diving, are also key growth catalysts. Advancements in manufacturing technologies, leading to cost reductions and improved production efficiencies, are further stimulating market penetration.

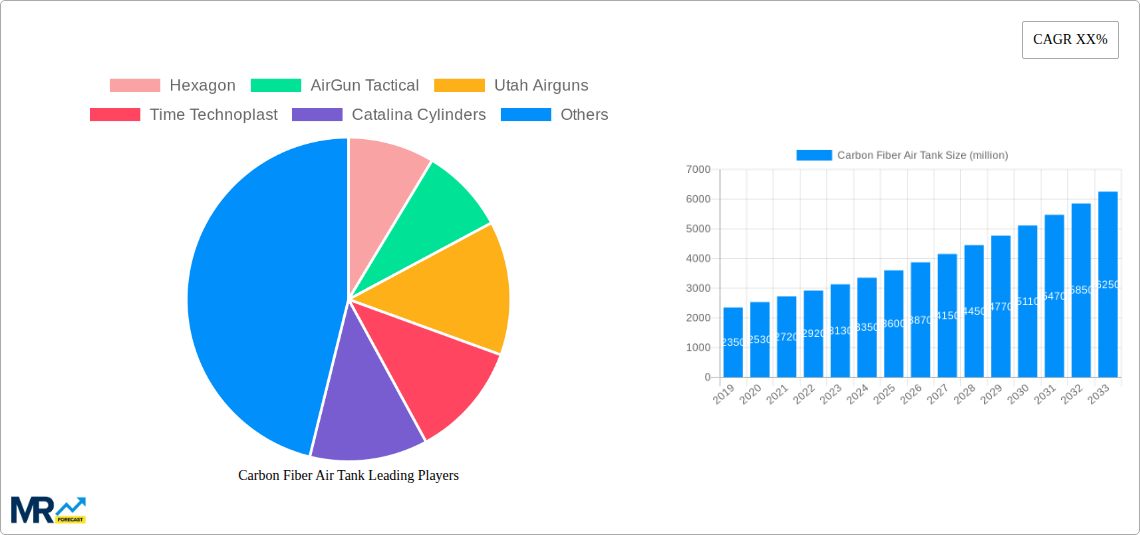

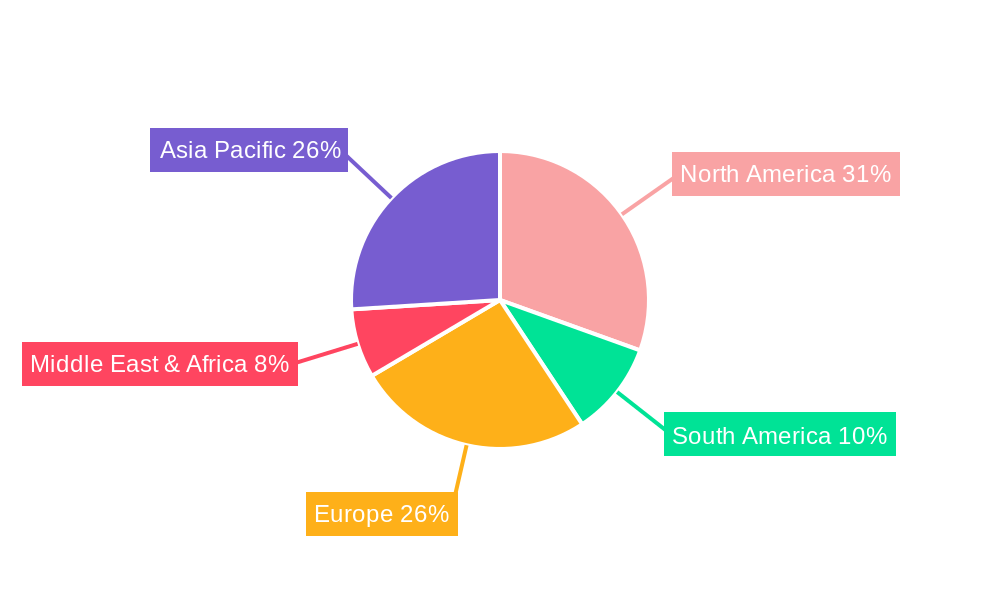

The market is characterized by a dynamic competitive landscape with key players like Hexagon, MSA Safety, and Catalina Cylinders investing heavily in research and development to innovate and expand their product portfolios. The dominance of Pan carbon fiber in terms of production volume is notable, owing to its established manufacturing processes and cost-effectiveness. However, Pitch and Rayon carbon fibers are gaining traction for specialized high-performance applications. Geographically, North America and Asia Pacific are leading the market, propelled by strong industrial bases and increasing adoption rates in automotive and aerospace sectors. Restraints, such as the relatively higher initial cost compared to traditional steel tanks and the need for specialized handling and disposal, are being addressed through technological advancements and evolving recycling initiatives. The market is segmented by type, including Pan Carbon Fiber, Pitch Carbon Fiber, and Rayon Carbon Fiber, and by application, encompassing Aerospace, Automotive, Firefighting, Private Use, and Others, all contributing to the overall market trajectory towards sustained high growth and innovation.

Here's a unique report description on Carbon Fiber Air Tanks, incorporating your specified values and structure:

This report offers an in-depth analysis of the global Carbon Fiber Air Tank market, meticulously tracing its trajectory from the historical period of 2019-2024, through the estimated base year of 2025, and extending into a robust forecast period of 2025-2033. With an emphasis on understanding the nuanced trends, driving forces, and critical challenges, this study provides a holistic view of the industry's evolution and future potential. Our research encompasses a detailed examination of market dynamics, including the identification of dominant segments and key regional players, alongside an exploration of significant technological advancements and strategic developments. The report quantifies market opportunities and threats, offering actionable insights for stakeholders seeking to navigate this dynamic and rapidly expanding sector. We delve into the manufacturing landscape, highlighting key companies and their contributions, and scrutinize the diverse applications driving demand. The projected market valuation and growth rates are presented with precision, enabling informed strategic decision-making. This report is an indispensable resource for manufacturers, suppliers, investors, and end-users seeking a comprehensive understanding of the global Carbon Fiber Air Tank market.

The global Carbon Fiber Air Tank market is poised for substantial expansion, driven by an escalating demand for lightweight, high-strength, and durable pressure vessels across a multitude of industries. Our analysis, spanning the historical period of 2019-2024 and extending through the forecast period of 2025-2033, with the base and estimated year of 2025, indicates a compound annual growth rate that will see the market size reach hundreds of millions of units by the end of the study period. A significant trend is the increasing adoption of carbon fiber composite technology over traditional metallic alternatives. This shift is fundamentally driven by the superior performance characteristics of carbon fiber, including its exceptional strength-to-weight ratio, corrosion resistance, and fatigue life. For instance, the Aerospace and Automotive sectors are increasingly specifying carbon fiber air tanks for their fuel systems and pneumatic applications, where weight reduction directly translates to improved fuel efficiency and enhanced performance. Furthermore, the growing emphasis on safety and performance in critical applications such as Firefighting and specialized Private Use (e.g., scuba diving, high-pressure air rifles) is a major catalyst. Manufacturers are continuously investing in research and development to optimize manufacturing processes, reduce production costs, and develop novel composite materials that further enhance the capabilities of these tanks. The market is segmented by type, including Pan Carbon Fiber, Pitch Carbon Fiber, and Ravon Carbon Fiber, each offering distinct properties tailored to specific application needs. The World Carbon Fiber Air Tank Production landscape is characterized by a concentration of technological expertise and manufacturing capabilities in select regions, which we will explore in detail. The overall trend points towards a market characterized by innovation, increasing adoption, and significant growth potential, with market valuations projected to ascend into the hundreds of millions of dollars as the industry matures and expands its reach.

The robust growth trajectory of the Carbon Fiber Air Tank market is underpinned by a confluence of powerful driving forces. Foremost among these is the relentless pursuit of weight reduction across industries where efficiency and performance are paramount. In the Aerospace sector, every kilogram saved translates directly into reduced fuel consumption and increased payload capacity, making carbon fiber air tanks an indispensable component for next-generation aircraft and spacecraft. Similarly, the Automotive industry's drive towards lighter vehicles to meet stringent fuel economy regulations and enhance electric vehicle range is significantly boosting demand for these advanced composite tanks, particularly for hydrogen storage and pneumatic systems. Beyond these large-scale applications, the increasing sophistication and performance demands in niche markets such as Firefighting equipment, professional diving, and high-pressure pneumatic systems are also significant contributors. Firefighters require lighter, more durable air tanks for self-contained breathing apparatus (SCBA) that offer extended operational times and enhanced safety. The burgeoning market for recreational activities like scuba diving and sporting goods, such as high-powered airguns, further amplifies this demand. Moreover, advancements in carbon fiber manufacturing technologies, including filament winding and resin infusion, are leading to more cost-effective production methods, thereby making these tanks more accessible for a broader range of applications and driving World Carbon Fiber Air Tank Production to new heights. The continuous innovation in resin systems and fiber reinforcement further enhances the performance characteristics, such as burst pressure and cyclic fatigue life, making carbon fiber an increasingly attractive alternative to traditional materials.

Despite the promising outlook, the Carbon Fiber Air Tank market is not without its challenges and restraints. A primary hurdle remains the higher initial cost of manufacturing compared to conventional metallic tanks. While advancements in production technologies are steadily reducing this gap, the capital expenditure required for specialized machinery and raw materials can still be a deterrent for some manufacturers and end-users, particularly in price-sensitive markets. Furthermore, the complex manufacturing processes involved in producing high-quality carbon fiber composite tanks necessitate skilled labor and stringent quality control measures, which can add to the overall production cost and lead time. The recycling and disposal of carbon fiber composites present another significant environmental and logistical challenge. Current recycling methods are often energy-intensive and can result in lower-grade recycled materials, limiting their reuse in high-performance applications. Developing more efficient and sustainable recycling processes is crucial for the long-term viability and environmental responsibility of the industry. Regulatory approvals and standardization can also pose a challenge, especially for new applications or novel tank designs. Obtaining certifications for safety and performance in critical sectors like aerospace and firefighting requires extensive testing and validation, which can be time-consuming and costly. Finally, consumer awareness and education regarding the benefits and proper handling of carbon fiber air tanks are still developing. Misconceptions about durability or repairability can hinder adoption in some segments. Addressing these challenges through continued innovation, cost optimization, and robust educational initiatives will be vital for unlocking the full market potential.

The global Carbon Fiber Air Tank market is characterized by distinct regional strengths and segment dominance. Considering the World Carbon Fiber Air Tank Production and its subsequent demand, North America, particularly the United States, is expected to lead the market in the coming years. This dominance is driven by a confluence of factors including robust demand from the Aerospace and Automotive industries, significant government investments in advanced materials research and development, and the presence of key players. The US also has a well-established market for specialized applications like high-pressure pneumatic firearms and recreational diving, contributing to a substantial portion of the Private Use segment.

In terms of specific segments, Pan Carbon Fiber tanks are likely to experience substantial growth and potentially dominate the market. This is due to their versatility and suitability for a wide array of pressure applications, including compressed natural gas (CNG) storage for vehicles, industrial gas cylinders, and SCBA systems. The inherent properties of Pan carbon fiber, such as its excellent tensile strength and stiffness, make it ideal for containing high pressures reliably and safely.

The Aerospace application segment is another major driver of market growth and dominance. The continuous drive for weight optimization in aircraft design makes carbon fiber air tanks a preferred choice for various onboard systems, from pneumatic actuators to emergency oxygen supplies. The stringent safety and performance requirements in this sector also necessitate the use of high-quality, advanced composite materials.

Furthermore, the Automotive sector, driven by the global push for emission reduction and fuel efficiency, is increasingly adopting carbon fiber tanks for hydrogen storage in fuel cell vehicles and for compressed air systems in conventional vehicles. This burgeoning demand is expected to significantly contribute to market growth and regional dominance, especially in countries with strong automotive manufacturing bases.

Key regions and countries that will play a pivotal role include:

North America (USA, Canada):

Europe (Germany, France, UK):

Asia-Pacific (China, Japan, South Korea):

The World Carbon Fiber Air Tank Production is increasingly influenced by these regions, with technological advancements and manufacturing capabilities concentrated in North America and Europe, while Asia-Pacific presents a substantial growth opportunity for production and consumption. The dominance of Pan Carbon Fiber within the Type segment, coupled with the substantial demand from Aerospace and Automotive applications, will shape the market landscape and regional leadership for the forecast period.

Several key growth catalysts are fueling the expansion of the Carbon Fiber Air Tank industry. The escalating demand for lightweight materials across Aerospace, Automotive, and defense sectors is a primary driver, directly translating to improved fuel efficiency and performance. Increasing global awareness and stringent regulations concerning safety and environmental protection are also pushing industries towards advanced, reliable pressure vessel solutions like carbon fiber tanks, particularly in applications like Firefighting and industrial gas handling. Furthermore, continuous technological advancements in carbon fiber manufacturing, leading to reduced production costs and enhanced material properties, are making these tanks more competitive and accessible. The growing popularity of high-pressure pneumatic systems in recreational activities and specialized industrial uses further broadens the market reach.

This comprehensive report provides a deep dive into the global Carbon Fiber Air Tank market, meticulously analyzing trends and opportunities from 2019 to 2033, with a focus on the base year of 2025. It identifies key growth catalysts such as the persistent demand for lightweight solutions in Aerospace and Automotive, driven by efficiency mandates and performance enhancements. The increasing stringency of safety regulations in sectors like Firefighting and the expanding market for high-pressure pneumatic systems in Private Use applications are also significant contributors. Furthermore, ongoing technological innovations in carbon fiber production and material science are consistently driving down costs and improving the performance characteristics of these tanks, making them increasingly competitive against traditional materials and paving the way for broader adoption across diverse applications and enhancing World Carbon Fiber Air Tank Production.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include Hexagon, AirGun Tactical, Utah Airguns, Time Technoplast, Catalina Cylinders, AMS Composite Cylinders, Faber Italy, First Strike FS, GladiatAir, Ninja Paintball, Air Venturi Wingman, Pyramyd Air, Air Tanks, Omega, MSA Safety, .

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Carbon Fiber Air Tank," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Carbon Fiber Air Tank, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.