1. What is the projected Compound Annual Growth Rate (CAGR) of the Automotive High Strength Steel?

The projected CAGR is approximately 4.9%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Automotive High Strength Steel

Automotive High Strength SteelAutomotive High Strength Steel by Type (Conventional HSS, AHSS), by Application (Commercial Vehicle, Passenger Vehicle), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

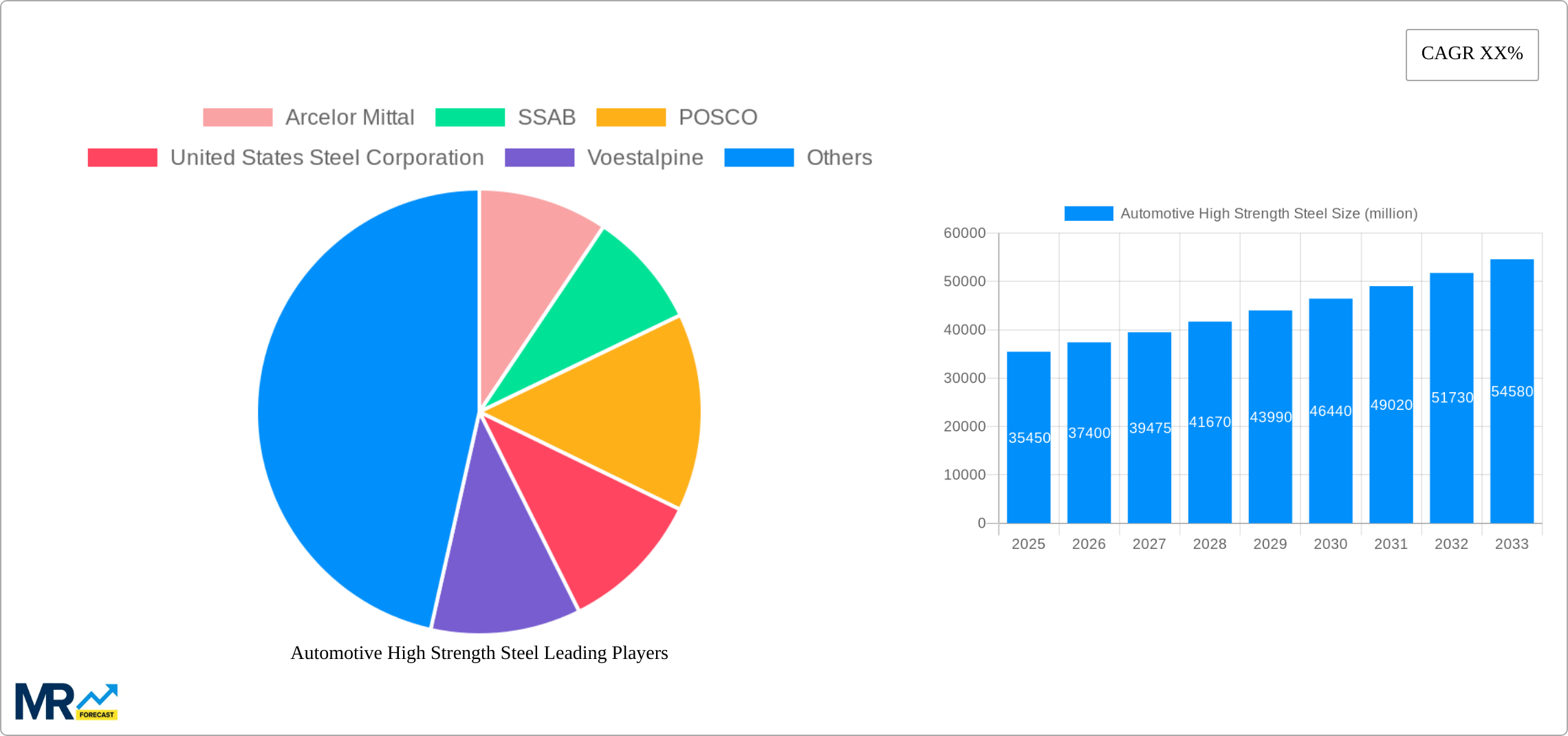

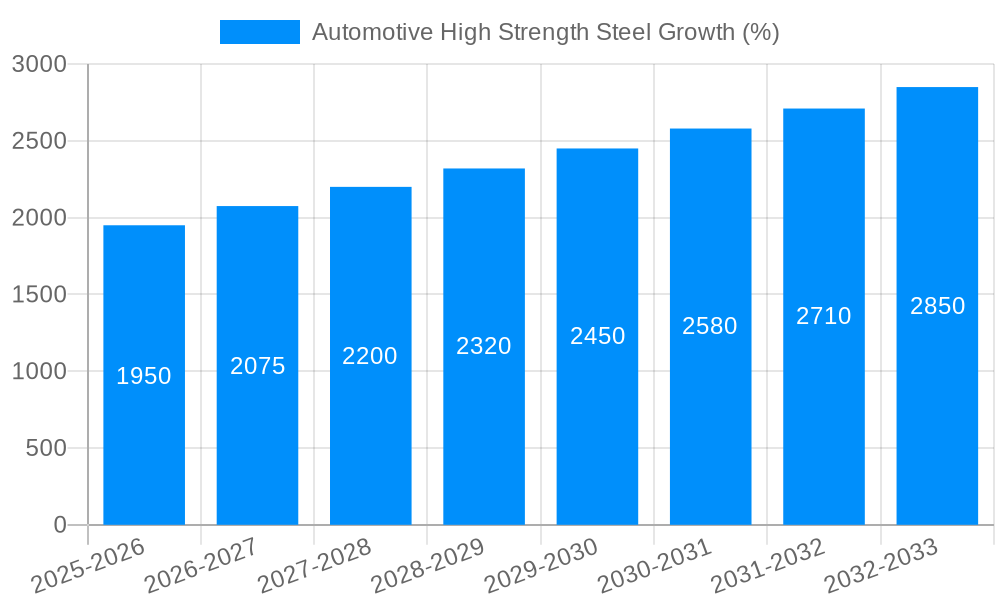

The global Automotive High Strength Steel (HSS) market is poised for substantial expansion, projected to reach an estimated market size of $25,390 million by 2025, exhibiting a robust Compound Annual Growth Rate (CAGR) of 4.9% throughout the forecast period of 2025-2033. This growth is intrinsically linked to the automotive industry's relentless pursuit of enhanced vehicle safety, improved fuel efficiency, and reduced environmental impact. As regulatory bodies worldwide increasingly prioritize stringent safety standards and emission targets, the demand for lighter yet stronger materials becomes paramount. Automotive HSS plays a critical role in enabling manufacturers to meet these demands by facilitating weight reduction without compromising structural integrity, thereby contributing to lower fuel consumption and reduced CO2 emissions. The market's trajectory is further bolstered by ongoing technological advancements in steel production, leading to the development of advanced grades of HSS with superior performance characteristics.

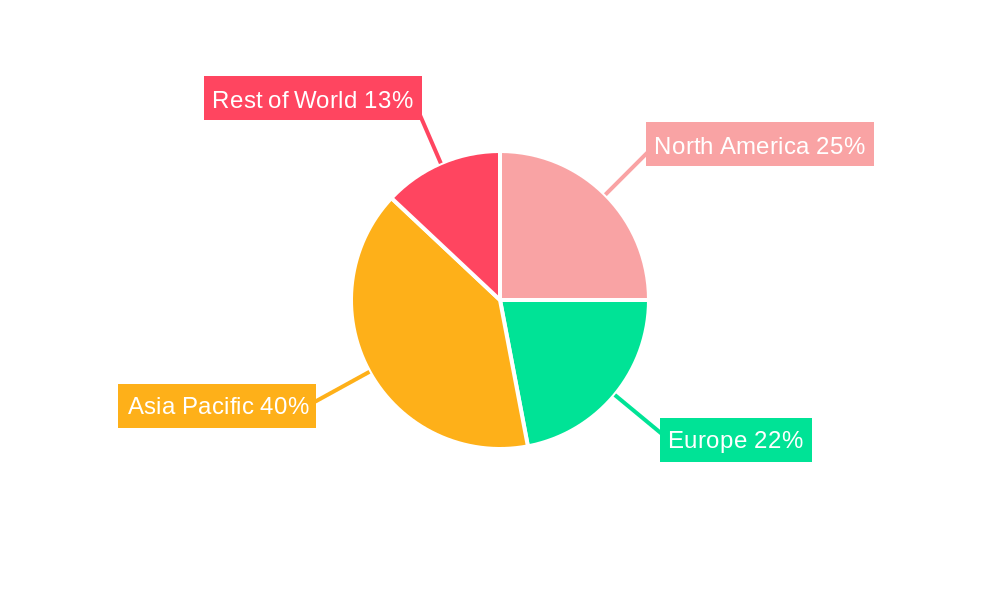

The market dynamics for Automotive HSS are shaped by a confluence of influential factors. Key growth drivers include the escalating production of commercial vehicles, which necessitate robust and durable materials for load-bearing applications, and the continuous innovation within the passenger vehicle segment, where lightweighting is a crucial strategy for improving performance and compliance with evolving environmental regulations. The industry is witnessing a significant shift towards Advanced High Strength Steels (AHSS) due to their exceptional strength-to-weight ratio and formability, offering automakers greater design flexibility and enhanced crashworthiness. While the market benefits from strong demand, potential restraints such as fluctuating raw material prices and the increasing adoption of alternative lightweight materials like aluminum and composites warrant strategic consideration by market participants. However, the inherent cost-effectiveness and established recycling infrastructure of steel are expected to maintain its competitive edge. Geographically, Asia Pacific, particularly China and India, is anticipated to be a dominant region, driven by its massive automotive production base and increasing adoption of advanced automotive technologies.

The global automotive high strength steel market is poised for significant expansion, driven by an unwavering commitment to enhanced vehicle safety, fuel efficiency, and evolving regulatory landscapes. Over the study period of 2019-2033, with a base year of 2025, the market is projected to witness a robust Compound Annual Growth Rate (CAGR) as automakers increasingly prioritize lighter yet stronger materials. In the historical period of 2019-2024, the market navigated initial challenges and began a steady upward trajectory. The estimated year of 2025 marks a pivotal point, where the market is expected to reach a substantial volume, setting the stage for sustained growth throughout the forecast period of 2025-2033. The adoption of Advanced High Strength Steel (AHSS) is particularly noteworthy, representing a paradigm shift from traditional High Strength Steel (HSS) due to its superior properties, enabling complex structural designs and substantial weight reduction. This transition is directly attributable to the escalating demands for improved crashworthiness without compromising on vehicle performance and environmental impact. Furthermore, the increasing global vehicle production, particularly in emerging economies, acts as a primary volume driver for high strength steel consumption. The intricate interplay between technological advancements in steel manufacturing, the growing consumer awareness regarding vehicle safety, and the push towards stricter emission standards are all contributing to the bullish outlook for automotive high strength steel. As the automotive industry continues its evolution towards electric vehicles (EVs), the need for lightweight materials to offset the battery weight becomes paramount, further solidifying the importance of high strength steels in this transformation. The industry is also witnessing a trend towards more specialized grades of AHSS, tailored for specific applications within a vehicle's structure, such as A-pillars, B-pillars, and side impact beams, all contributing to a more sophisticated and integrated approach to vehicle design. The market's trajectory indicates a clear preference for materials that offer an optimal balance of strength, ductility, and formability, thereby enabling manufacturers to produce safer, more fuel-efficient, and ultimately, more competitive vehicles in the global marketplace.

The automotive high strength steel market is experiencing a powerful surge, fueled by a confluence of critical factors. Foremost among these is the unrelenting global focus on vehicle safety. Stringent crash test regulations and a heightened consumer awareness regarding occupant protection necessitate the use of materials that can effectively absorb impact energy and maintain structural integrity during collisions. High strength steels, particularly AHSS grades, excel in this regard, offering superior tensile strength and energy absorption capabilities compared to conventional steels. Coupled with safety, the imperative for enhanced fuel efficiency and reduced emissions stands as another significant propellant. Automakers are under immense pressure to meet increasingly stringent environmental standards, and lightweighting vehicles is a primary strategy to achieve this. By replacing heavier traditional steels with lighter, high strength alternatives, manufacturers can significantly reduce a vehicle's overall weight, leading to improved fuel economy and lower greenhouse gas emissions. This weight reduction is crucial not only for internal combustion engine vehicles but also for electric vehicles, where it helps to offset the substantial weight of battery packs, thereby extending range and improving performance. The continuous innovation in steel manufacturing processes, leading to the development of novel AHSS grades with improved properties like formability and weldability, further empowers automotive designers and engineers to incorporate these advanced materials more extensively across various vehicle components.

Despite the robust growth trajectory, the automotive high strength steel market is not without its hurdles. A primary challenge lies in the increased cost of manufacturing for advanced high strength steel grades. The complex metallurgical processes and specialized equipment required for their production often translate into a higher price point compared to conventional steels. This cost differential can be a significant deterrent for some automakers, especially in cost-sensitive segments of the market or during periods of economic downturn. Furthermore, the complex formability and processing requirements of certain AHSS grades present another significant restraint. While their superior strength is advantageous, it also makes them more challenging to shape, cut, and weld using traditional automotive manufacturing techniques. This often necessitates investment in new tooling, machinery, and employee training, adding to the overall implementation costs and complexity for manufacturers. The availability of alternative lightweight materials, such as aluminum alloys and composites, also poses a competitive threat. While steel manufacturers are continuously innovating, these alternatives offer their own unique advantages, including even lower weight in some cases, which can divert market share, particularly for premium or specialized applications. Finally, the global supply chain complexities and raw material price volatility can impact the consistent and cost-effective supply of high strength steel, introducing an element of uncertainty for long-term production planning and market stability.

The global automotive high strength steel market is characterized by the significant dominance of Asia-Pacific, driven by its colossal automotive manufacturing base and robust demand for new vehicles. Within this region, China stands out as a paramount contributor, owing to its status as the world's largest automobile producer and consumer. The country's aggressive push towards higher safety standards and the rapid growth of its domestic automotive industry, encompassing both passenger vehicles and an increasing volume of commercial vehicles, directly translates to a substantial demand for high strength steels. The Chinese government's supportive policies for the automotive sector and its significant investments in advanced manufacturing technologies further bolster its leading position.

Another key region exerting considerable influence is North America, particularly the United States. The region's mature automotive industry, with its emphasis on safety and fuel efficiency, has been an early adopter of advanced high strength steels. The stringent safety regulations implemented by the National Highway Traffic Safety Administration (NHTSA) and the ongoing trend of vehicle lightweighting to meet Corporate Average Fuel Economy (CAFE) standards have been instrumental in driving the adoption of HSS and AHSS. The significant presence of major automotive OEMs and their extensive manufacturing footprints in the U.S. solidify its importance in the market.

In terms of segment dominance, Advanced High Strength Steel (AHSS) is unequivocally leading the charge and is projected to continue its ascendant path. This is primarily due to its inherent superior properties that directly address the core demands of the modern automotive industry – enhanced safety and weight reduction. AHSS encompasses a range of steel grades, including Dual Phase (DP), Complex Phase (CP), Transformation Induced Plasticity (TRIP), Martensitic (MS), and Press Hardened Steels (PHS), each offering a unique combination of strength, ductility, and formability. The Passenger Vehicle segment is the primary application area driving the demand for AHSS. As consumer expectations for safety continue to rise, and manufacturers strive to produce more fuel-efficient and lighter cars, AHSS finds extensive application in critical structural components such as body-in-white (BIW) structures, pillars, side impact beams, and crash energy management systems. The ability of AHSS to be used in thinner sections while maintaining structural integrity allows for significant weight savings in passenger cars, directly contributing to improved fuel economy and reduced emissions, key selling points in this competitive market.

The automotive high strength steel industry is propelled by several key growth catalysts. The relentless pursuit of enhanced vehicle safety, driven by stringent global regulations and consumer demand, remains a primary driver. As automotive manufacturers strive to meet and exceed crashworthiness standards, the adoption of higher-strength steels becomes indispensable. Furthermore, the escalating focus on fuel efficiency and emissions reduction compels automakers to lightweight vehicles, a goal significantly achieved through the use of high strength steels. The burgeoning electric vehicle (EV) market also acts as a significant catalyst, as the need to offset heavy battery packs necessitates lighter chassis and body structures, directly benefiting high strength steel consumption.

This comprehensive report offers an in-depth analysis of the global automotive high strength steel market, providing critical insights for stakeholders. It delves into market size and volume estimations, projecting figures in the million unit range across the study period of 2019-2033, with a focused analysis on the base year of 2025 and the forecast period of 2025-2033. The report meticulously examines the historical market trends from 2019 to 2024, highlighting the foundational growth and evolutionary phases. It dissects the market into key segments, including Conventional HSS and AHSS, and further categorizes by application into Commercial Vehicle and Passenger Vehicle. The report also scrutinizes pivotal industry developments, identifying key market drivers, challenges, and restraints that shape the competitive landscape. Through detailed regional analysis, it pinpoints dominant geographies and their underlying market dynamics. This report equips industry participants with the strategic intelligence necessary to navigate the evolving automotive high strength steel sector.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 4.9% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately 4.9%.

Key companies in the market include Arcelor Mittal, SSAB, POSCO, United States Steel Corporation, Voestalpine, ThyssenKrupp, Baowu Group, Ansteel, .

The market segments include Type, Application.

The market size is estimated to be USD 25390 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3480.00, USD 5220.00, and USD 6960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Automotive High Strength Steel," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Automotive High Strength Steel, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.