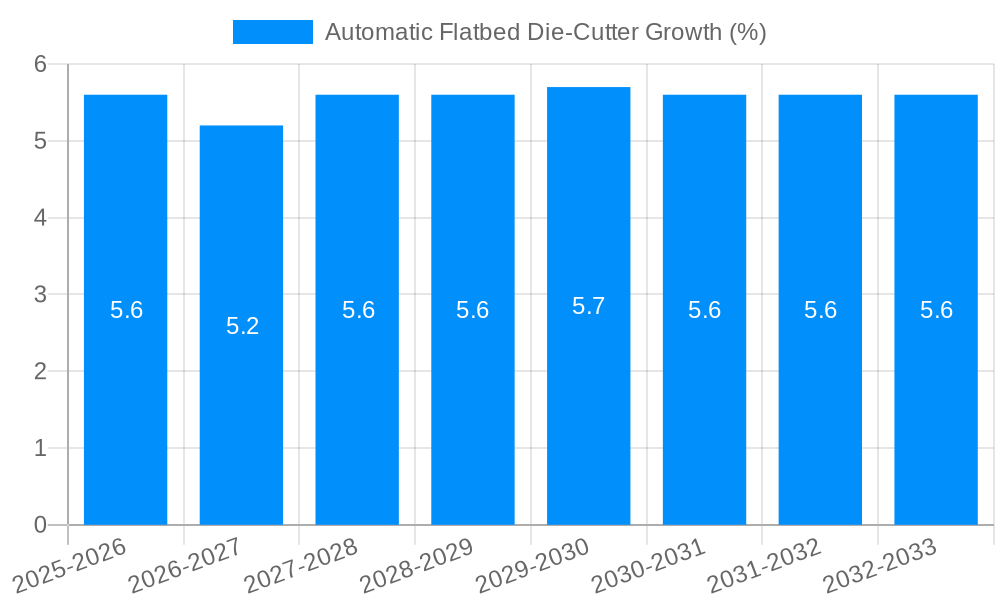

1. What is the projected Compound Annual Growth Rate (CAGR) of the Automatic Flatbed Die-Cutter?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Automatic Flatbed Die-Cutter

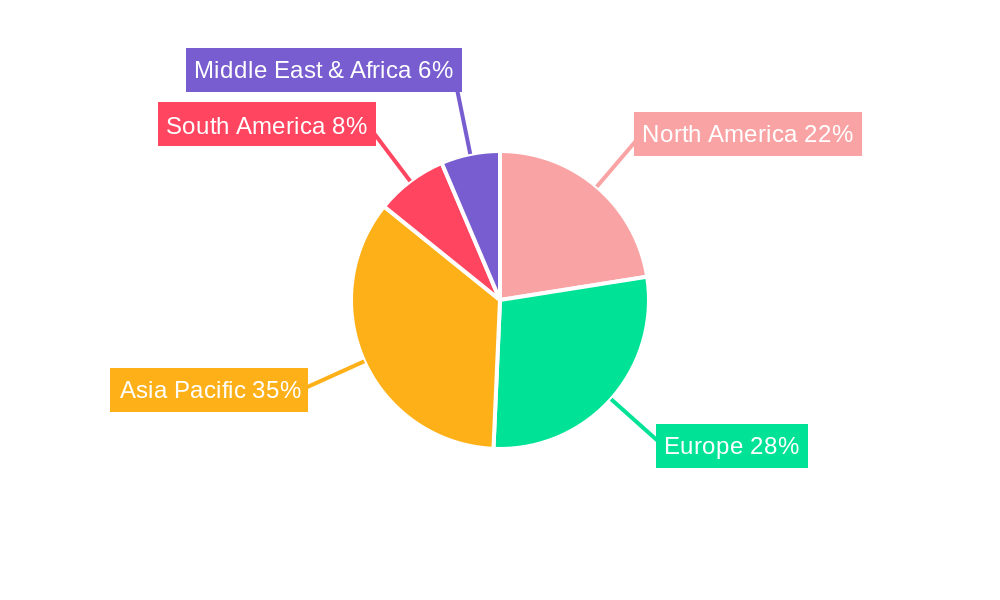

Automatic Flatbed Die-CutterAutomatic Flatbed Die-Cutter by Type (Blade Cutting, Laser Cutting, World Automatic Flatbed Die-Cutter Production ), by Application (Medical, Flexible Circuits, Digital Printing, Electric Vehicle Batteries, Others, World Automatic Flatbed Die-Cutter Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

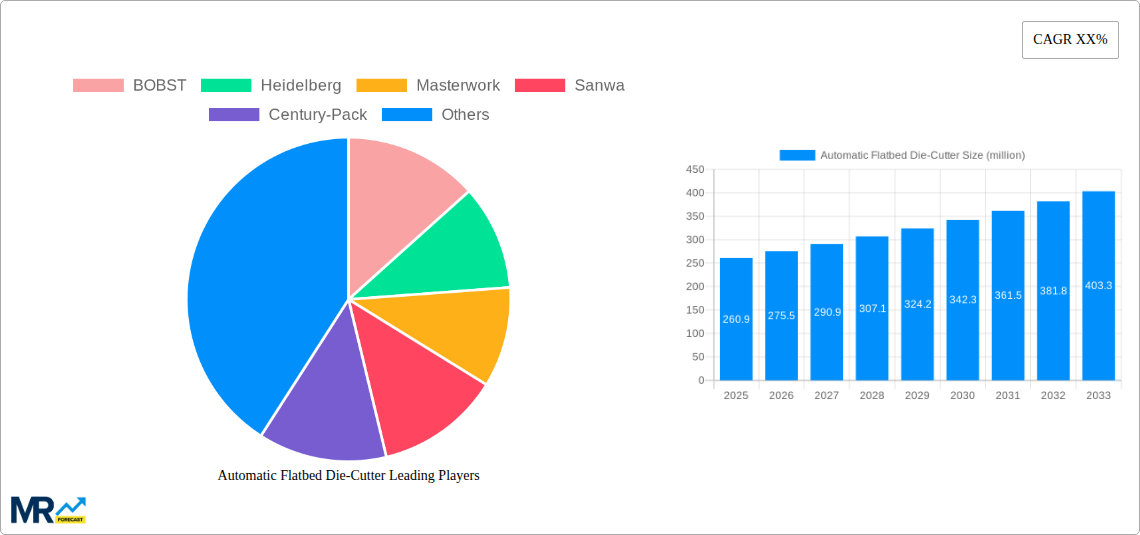

The global Automatic Flatbed Die-Cutter market is poised for significant expansion, currently valued at an estimated USD 260.9 million. This robust growth is fueled by a confluence of factors, primarily the escalating demand for precision cutting in high-growth sectors such as medical devices, flexible circuits, and electric vehicle batteries. The increasing adoption of digital printing technologies also plays a crucial role, driving the need for efficient and accurate finishing solutions that automatic flatbed die-cutters provide. Furthermore, advancements in technology, leading to more sophisticated, faster, and versatile machines, are actively contributing to market penetration. The ability of these die-cutters to handle complex geometries and a wide range of materials efficiently translates into enhanced productivity and reduced waste for manufacturers, making them an indispensable investment across various industries.

The market is characterized by a dynamic competitive landscape, with key players like BOBST, Heidelberg, and Masterwork continuously innovating to offer advanced solutions. The CAGR projected for this market indicates a healthy growth trajectory, suggesting that the demand for automatic flatbed die-cutters will outpace general industrial production growth. While the initial investment can be substantial, the long-term benefits in terms of operational efficiency, product quality, and market competitiveness are driving adoption, particularly in regions with strong manufacturing bases. The increasing complexity of product designs in sectors like automotive and electronics further necessitates the precision and automation that these machines offer, solidifying their position as critical components in modern manufacturing workflows.

Here's a comprehensive report description for the Automatic Flatbed Die-Cutter market, incorporating your specified elements:

This in-depth market analysis provides a panoramic view of the global Automatic Flatbed Die-Cutter market, meticulously examining its trajectory from the Historical Period (2019-2024) through to a robust Forecast Period (2025-2033), with a deep dive into the Base Year (2025) and Estimated Year (2025). The report delves into the intricate dynamics influencing this crucial manufacturing technology, presenting data in the million unit for production volumes and market values. Our analysis encompasses a detailed breakdown of the market by Type, including the dominant Blade Cutting and the rapidly evolving Laser Cutting technologies. We also explore the diverse Application segments, with particular emphasis on the burgeoning demand from Medical, the high-precision requirements of Flexible Circuits, the transformative impact of Digital Printing, and the critical role in Electric Vehicle Batteries manufacturing, alongside other specialized applications. Furthermore, the report meticulously tracks World Automatic Flatbed Die-Cutter Production trends and crucial Industry Developments. This comprehensive report is an indispensable resource for stakeholders seeking to navigate and capitalize on the opportunities within the global Automatic Flatbed Die-Cutter landscape.

The global Automatic Flatbed Die-Cutter market is currently experiencing a significant paradigm shift, driven by an accelerating demand for precision, efficiency, and automation across a multitude of industries. The Study Period (2019-2033) reveals a consistent upward trend in production volumes, projected to reach an impressive figure of X million units by the end of the forecast period. This growth is underpinned by several key insights. Firstly, the increasing adoption of digital printing technologies has created a symbiotic relationship with flatbed die-cutters, enabling on-demand, short-run production of complex packaging and labels with intricate shapes and designs. This has particularly benefited the packaging segment, which continues to be a major consumer of these machines. Secondly, the rise of high-value, niche applications such as medical device components and flexible electronic circuits is pushing the boundaries of what flatbed die-cutters can achieve. The stringent quality control and accuracy required in these sectors are driving innovation in cutting technologies, with laser cutting gaining considerable traction due to its non-contact nature and ability to achieve intricate patterns. The Base Year (2025) is a pivotal point, reflecting a market segment already valuing in the billions, with projected steady growth in the subsequent years. The market is also witnessing a geographical redistribution of production, with Asia-Pacific emerging as a dominant manufacturing hub, driven by cost-effectiveness and a burgeoning domestic demand. Automation and Industry 4.0 principles are also deeply ingrained in the current trends, with manufacturers investing heavily in smart machines featuring advanced sensor technology, predictive maintenance capabilities, and seamless integration with other manufacturing processes. The evolution from traditional blade cutting to more advanced laser cutting solutions is a testament to the industry's commitment to enhancing precision, reducing material waste, and improving overall operational efficiency. This ongoing technological evolution ensures that the Automatic Flatbed Die-Cutter remains a cornerstone of modern manufacturing.

The Automatic Flatbed Die-Cutter market is being propelled forward by a confluence of powerful economic and technological drivers. A primary force is the escalating global demand for personalized and customized packaging solutions. As consumer preferences diversify and brands strive for unique product differentiation, the need for high-precision, efficient die-cutting becomes paramount for creating intricate shapes, window cutouts, and specialized finishes. This surge in demand is particularly evident in sectors like food and beverage, cosmetics, and e-commerce, where packaging plays a crucial role in brand perception and customer experience. Furthermore, the rapid advancement in digital printing technologies has unlocked new possibilities for short-run, on-demand production, a capability perfectly complemented by the flexibility and accuracy of automatic flatbed die-cutters. The growing emphasis on sustainability and waste reduction across industries is another significant catalyst. Modern die-cutters, especially those employing advanced laser cutting technologies, offer superior material utilization and minimize scrap, aligning with the industry's commitment to environmentally responsible manufacturing practices. The expansion of industries requiring highly specialized components, such as the medical sector for device manufacturing and the electronics sector for flexible circuits, is also contributing to market growth. These applications necessitate extremely high precision and meticulous cutting, areas where advanced flatbed die-cutting solutions excel.

Despite its robust growth trajectory, the Automatic Flatbed Die-Cutter market faces several significant challenges and restraints that warrant careful consideration. One of the primary hurdles is the substantial initial investment required for acquiring these sophisticated machines. The advanced technology, precision engineering, and integrated automation features contribute to a high capital expenditure, which can be a deterrent for small and medium-sized enterprises (SMEs) or businesses in emerging economies. This financial barrier can limit market penetration and slow down adoption rates in certain regions. Another challenge lies in the complex nature of maintaining and operating these advanced systems. While automation is a key feature, it also necessitates a skilled workforce capable of handling software integration, calibration, and troubleshooting. The scarcity of adequately trained technicians and operators can lead to downtime and impact overall productivity, thus acting as a restraint on market growth. Furthermore, the rapidly evolving technological landscape presents a continuous need for upgrades and innovation. Companies must constantly invest in research and development to keep pace with emerging cutting technologies, material science advancements, and evolving industry standards. Failure to do so can result in a loss of competitive edge. The availability and cost fluctuations of raw materials, such as specialized cutting materials and components, can also impact the profitability and production schedules of die-cutter manufacturers and end-users alike. Finally, stringent regulatory requirements in certain application sectors, particularly in the medical and food industries, add another layer of complexity, demanding rigorous compliance and validation processes.

The global Automatic Flatbed Die-Cutter market is poised for significant growth and diversification, with certain regions and segments standing out as key dominators. Analyzing the World Automatic Flatbed Die-Cutter Production data, the Asia-Pacific region, particularly China, is emerging as a powerhouse, not only in terms of production volume but also as a rapidly expanding consumer market. This dominance is fueled by several factors: a large and growing manufacturing base across diverse industries, a significant push towards automation and Industry 4.0 adoption, and a competitive manufacturing cost structure that attracts global players. Countries like South Korea and Japan also contribute significantly due to their advanced technological capabilities and strong presence in high-tech sectors.

Within the Application segments, the Digital Printing sector is a significant driver of market dominance. The increasing adoption of digital printing for packaging, labels, and signage necessitates precise and efficient finishing solutions, making automatic flatbed die-cutters indispensable. This segment benefits from the trend towards shorter print runs, personalization, and on-demand production, where the speed and accuracy of flatbed die-cutters are crucial.

Another key segment demonstrating strong growth and dominance is Medical. The stringent requirements for precision, sterility, and accuracy in the manufacturing of medical devices, diagnostic kits, and pharmaceutical packaging have made advanced flatbed die-cutters a critical component. The ability of these machines to cut complex shapes from sensitive materials with extremely tight tolerances is paramount. The demand here is driven by an aging global population, advancements in healthcare technologies, and the increasing need for disposable medical supplies.

The Flexible Circuits application segment is also a key contributor to market dominance, particularly in advanced manufacturing hubs. The miniaturization and increasing complexity of electronic devices require highly precise cutting of flexible substrates for printed circuit boards (PCBs) and other electronic components. The non-contact nature of laser cutting, a type of technology within flatbed die-cutters, makes it ideal for these delicate materials, minimizing damage and ensuring high yields.

The Blade Cutting Type continues to hold a substantial market share due to its cost-effectiveness and suitability for a wide range of materials and applications, especially in traditional packaging. However, the Laser Cutting Type is experiencing the fastest growth rate. Its ability to deliver unparalleled precision, intricate designs, and to process a broader spectrum of materials, including those that are difficult to cut with blades, is driving its adoption in high-value applications like flexible circuits and certain segments of medical device manufacturing. The synergy between these two cutting technologies allows the market to cater to a diverse range of needs, further solidifying the dominance of specific regions and segments in the overall World Automatic Flatbed Die-Cutter Production.

The Automatic Flatbed Die-Cutter industry is experiencing significant growth catalysts that are shaping its future. The relentless push towards automation and Industry 4.0 adoption across manufacturing sectors is a primary driver, enhancing operational efficiency and reducing labor costs. The burgeoning e-commerce landscape, with its demand for specialized, protective, and aesthetically pleasing packaging, is creating substantial opportunities. Furthermore, advancements in material science are enabling the use of new, innovative substrates, which flatbed die-cutters are increasingly equipped to handle. The growing emphasis on sustainable packaging solutions also plays a crucial role, as precise die-cutting minimizes material waste.

The global Automatic Flatbed Die-Cutter market is characterized by the presence of several influential players, each contributing to innovation and market expansion. The leading companies shaping this industry include:

The Automatic Flatbed Die-Cutter sector has witnessed a series of significant developments that have propelled its evolution. These advancements reflect a continuous pursuit of precision, speed, and automation:

This comprehensive report offers a deep dive into the Automatic Flatbed Die-Cutter market, providing invaluable insights for strategic decision-making. It meticulously analyzes market size and forecasts, projecting production volumes to reach X million units by 2033, with the Base Year (2025) serving as a critical benchmark. The report details the competitive landscape, profiling key players and their strategic initiatives. Furthermore, it dissects market segmentation by technology (Blade Cutting, Laser Cutting) and application (Medical, Flexible Circuits, Digital Printing, Electric Vehicle Batteries, and Others), highlighting growth drivers and opportunities within each. The analysis of World Automatic Flatbed Die-Cutter Production and Industry Developments ensures a complete understanding of the market's current state and future trajectory. Stakeholders can leverage this report to identify emerging trends, assess competitive threats, and capitalize on burgeoning market segments.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include BOBST, Heidelberg, Masterwork, Sanwa, Century-Pack, Koenig&Bauer Iberica SA, SBL, Young Shin, ASAHI MACHINERY LIMITED, Sysco Machinery, ATOM, Shanghai Yawa Printing Machinery, Chiesa, BERHALTER AG, Jih Shuenn, IIJIMA MFG, Spartanics, Baysek Machines, .

The market segments include Type, Application.

The market size is estimated to be USD 260.9 million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Automatic Flatbed Die-Cutter," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Automatic Flatbed Die-Cutter, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.