1. What is the projected Compound Annual Growth Rate (CAGR) of the Anti Corrosive Epoxy Paint?

The projected CAGR is approximately XX%.

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.

Anti Corrosive Epoxy Paint

Anti Corrosive Epoxy PaintAnti Corrosive Epoxy Paint by Type (Single Component, Two Component, World Anti Corrosive Epoxy Paint Production ), by Application (Marine Engineering, Transportation, Energy Industry, Others, World Anti Corrosive Epoxy Paint Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

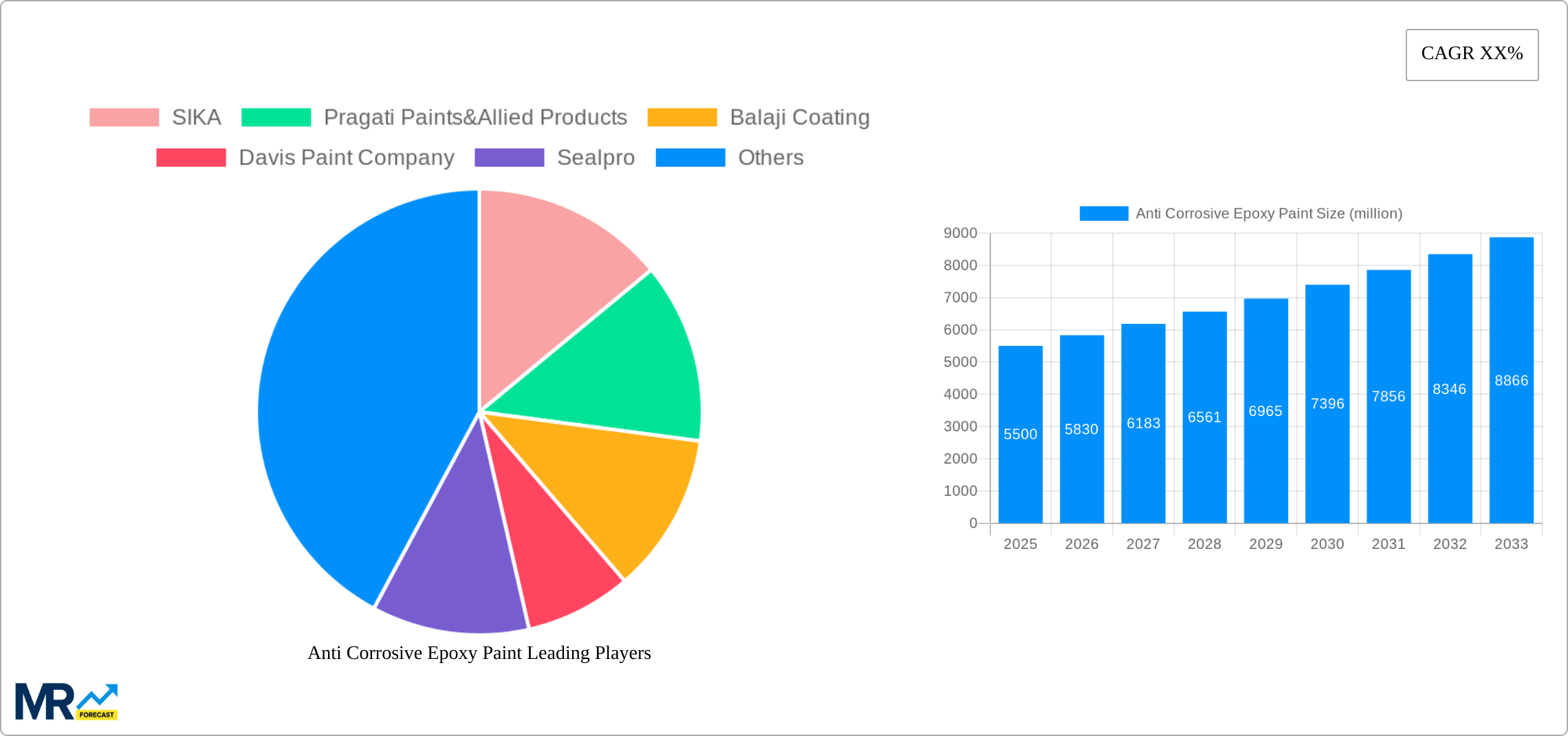

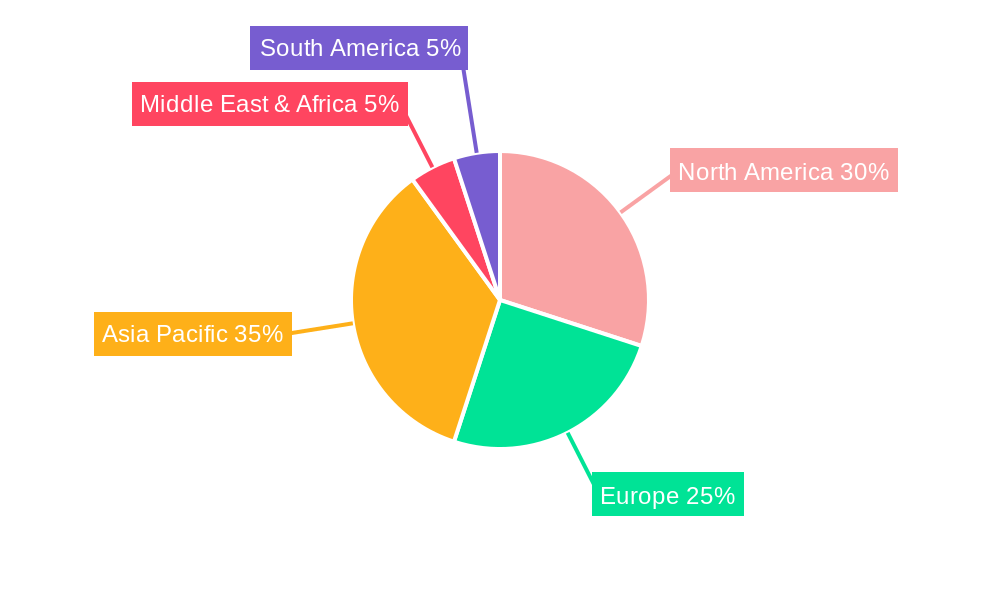

The global anti-corrosive epoxy paint market is experiencing robust growth, driven by the increasing demand for protective coatings across diverse industries. The expanding infrastructure development, particularly in emerging economies, coupled with stringent regulations concerning environmental protection and asset lifespan extension, are key factors fueling market expansion. The construction sector, including bridges, pipelines, and buildings, constitutes a significant portion of the demand, alongside the marine and transportation industries, where corrosion prevention is crucial for ensuring operational safety and efficiency. Technological advancements in epoxy paint formulations, leading to improved durability, enhanced adhesion, and faster curing times, are further propelling market growth. The market is segmented by type (single-component and two-component) and application (marine engineering, transportation, energy, and others). While the single-component segment currently holds a larger market share due to ease of application and lower cost, the two-component segment is projected to witness faster growth owing to its superior performance characteristics. Regionally, North America and Europe currently dominate the market due to established infrastructure and stringent environmental regulations. However, rapid industrialization and infrastructure development in Asia-Pacific are expected to drive substantial growth in this region over the forecast period. The market faces challenges such as fluctuating raw material prices and the potential for volatile economic conditions to impact investment in infrastructure projects. Nevertheless, the long-term outlook for the anti-corrosive epoxy paint market remains positive, driven by ongoing investments in infrastructure and the increasing awareness of the economic and environmental benefits of corrosion prevention.

The competitive landscape is characterized by the presence of both established multinational players and regional manufacturers. Key market participants are continuously investing in research and development to improve product performance and expand their product portfolio. Strategic partnerships, mergers and acquisitions, and the development of novel product formulations are key strategies employed by companies to gain a competitive edge. The market is expected to consolidate further in the coming years, with larger players acquiring smaller companies to expand their market reach and enhance their technological capabilities. The increasing emphasis on sustainable and eco-friendly coating solutions is creating new opportunities for manufacturers to develop and market environmentally responsible products. This includes the use of bio-based raw materials and the development of low-VOC (Volatile Organic Compound) paints. The continuous growth in renewable energy projects and increasing demand for corrosion protection in harsh environments further supports market expansion.

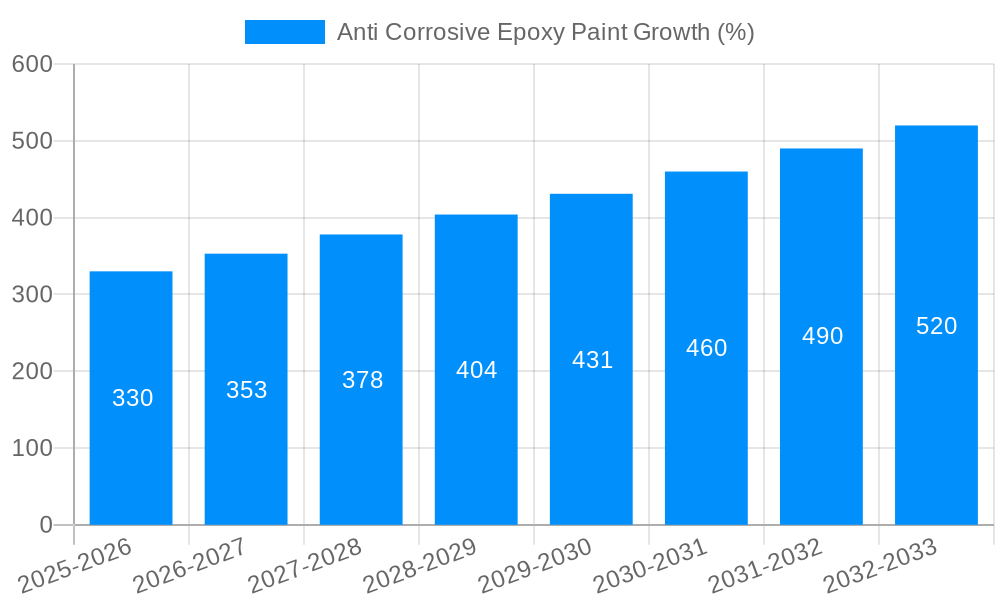

The global anti-corrosive epoxy paint market is experiencing robust growth, projected to reach several billion USD by 2033. Driven by increasing infrastructure development, particularly in emerging economies, and a heightened awareness of the long-term costs associated with corrosion, the demand for high-performance anti-corrosive coatings is steadily rising. The market is witnessing a shift towards eco-friendly, low-VOC (volatile organic compound) epoxy paints, reflecting growing environmental concerns. Innovation in formulation is another key trend, with manufacturers focusing on developing coatings with enhanced durability, resistance to extreme temperatures and chemicals, and improved application methods. This includes advancements in UV resistance for outdoor applications and specialized coatings designed for specific industries like marine engineering and oil & gas. The market is also seeing increased consolidation, with larger players acquiring smaller companies to expand their product portfolios and geographical reach. This consolidation contributes to increased competition and drives innovation within the industry. Finally, the ongoing development and adoption of advanced application technologies, such as robotic spraying and powder coating, are streamlining the application process and improving efficiency. These trends collectively point to a dynamic and expanding market with significant opportunities for growth in the coming years. The overall market size, valued at approximately X billion USD in 2025, is expected to experience a Compound Annual Growth Rate (CAGR) of Y% during the forecast period (2025-2033), surpassing Z billion USD by the end of the forecast period. This remarkable growth is fueled by the factors discussed above.

Several factors are driving the growth of the anti-corrosive epoxy paint market. The burgeoning global infrastructure development projects, including construction of bridges, pipelines, buildings, and ships, are significantly contributing to the demand for protective coatings. The rising need to extend the lifespan of assets, particularly in harsh environments, is another major driver. Corrosion costs billions of dollars annually in maintenance and repairs across various industries. The adoption of anti-corrosive epoxy paints offers a cost-effective solution by preventing corrosion and minimizing costly repairs in the long run. Stringent environmental regulations worldwide are also pushing the market towards the development and adoption of eco-friendly, low-VOC epoxy paints. This trend is increasing the demand for sustainable and environmentally compliant coatings. Furthermore, the growing awareness among consumers and businesses about the importance of corrosion protection is boosting the market. This increased awareness leads to greater investment in preventative maintenance and the adoption of high-quality anti-corrosive coatings like epoxy paints. The continuous development of new and improved formulations with enhanced properties like UV resistance, chemical resistance, and higher durability further fuels market expansion.

Despite the significant growth potential, the anti-corrosive epoxy paint market faces several challenges. Fluctuations in raw material prices, particularly for resins and pigments, can impact profitability and affect market stability. The stringent regulatory landscape surrounding VOC emissions necessitates investments in research and development to create environmentally compliant products, adding to the manufacturing costs. The competitive nature of the market, with numerous players vying for market share, necessitates continuous innovation and aggressive marketing strategies to maintain a competitive edge. Furthermore, the relatively high initial cost of application, compared to other protective coatings, can be a barrier to adoption, especially for budget-constrained projects. Finally, the need for skilled labor for proper surface preparation and application can pose a challenge in certain regions, leading to inconsistent results and potentially reduced product lifespan.

The Asia-Pacific region is expected to dominate the anti-corrosive epoxy paint market during the forecast period due to rapid industrialization, infrastructure development, and significant investments in construction projects. Within this region, countries like China and India are leading the growth.

In terms of market share by region, the Asia Pacific region is estimated to account for approximately X million USD in 2025, significantly higher than other regions such as North America, Europe, and the rest of the world. This dominance is attributed to rapid economic growth, ongoing industrialization, and substantial investments in infrastructure projects within the region, creating a robust demand for high-performance corrosion protection solutions. The robust growth in the Asia Pacific market is further driven by the growing shipbuilding industry, the expansion of oil and gas pipelines, and increasing construction of large-scale infrastructure projects like bridges and skyscrapers.

The growth of the anti-corrosive epoxy paint market is further catalyzed by the increasing adoption of advanced technologies in the manufacturing and application processes. These advancements lead to improved product quality, higher efficiency, and reduced environmental impact. Furthermore, government initiatives promoting sustainable construction practices and infrastructure development play a pivotal role in stimulating market growth. The increasing demand for specialized epoxy paints designed to withstand harsh environmental conditions in specific industries such as oil and gas, and marine engineering also contributes significantly to the overall market expansion.

This report provides a comprehensive analysis of the anti-corrosive epoxy paint market, offering valuable insights into market trends, driving forces, challenges, and key players. It details the market size and growth projections for the forecast period (2025-2033), offering segmented data by region, application, and product type. The report also highlights significant developments and technological advancements in the industry, allowing stakeholders to make well-informed business decisions. The data utilized draws from a combination of primary and secondary research methodologies, ensuring comprehensive and reliable insights into this dynamic and fast-growing market.

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Note*: In applicable scenarios

Primary Research

Secondary Research

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

The projected CAGR is approximately XX%.

Key companies in the market include SIKA, Pragati Paints&Allied Products, Balaji Coating, Davis Paint Company, Sealpro, APV Engineered Coatings, Warren Paint & Color Co., Benjamin Moore, Pruett-Schaffer, Crown Paint Company, United Gilsonite Laboratories, Harrison Paint Company, Mitsui Chemicals, Inc., Dai Nippon Toryo Company, Endura Paint, BOYSEN, Protek Paint, Majestic Chemicals Industries, KANSAI HELIOS, Maydos Group, Guangxi Shun Mei New Materials Co., Shandong Bridge Paint Co..

The market segments include Type, Application.

The market size is estimated to be USD XXX million as of 2022.

N/A

N/A

N/A

N/A

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4480.00, USD 6720.00, and USD 8960.00 respectively.

The market size is provided in terms of value, measured in million and volume, measured in K.

Yes, the market keyword associated with the report is "Anti Corrosive Epoxy Paint," which aids in identifying and referencing the specific market segment covered.

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

To stay informed about further developments, trends, and reports in the Anti Corrosive Epoxy Paint, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.